Industrial Crossover Stairs

Banks Industrial Group (BIG) sells and installs OSHA-compliant ErectaStep crossover stairs, ladders, catwalks, and access platforms. Pre-engineered for streamlined installation, these systems provide easy access to control equipment and enable safe, easy passage over pipes, dike walls, conveyor belts, and other obstructions. From quote to installation, these high-quality platforms can be pulled off the shelves and, in many cases, shipped within a day.

With an ErectaStep system, you benefit from the following:

-

Unlimited configuration possibilities

-

Customizable walking surface length

-

Rapid installation and support

-

Fast, detailed quotes (drawings included)

-

Precision manufacturing in the USA

BIG prides itself on being able to ship and install the ErectaStep system faster than most companies can issue a purchase order.

Request Crossover Stairs Estimate

Product Description

-

Pre-engineered industrial crossover stairs

-

Prevents slips, trips and falls before they happen

-

Improves productivity by facilitating better worker access

-

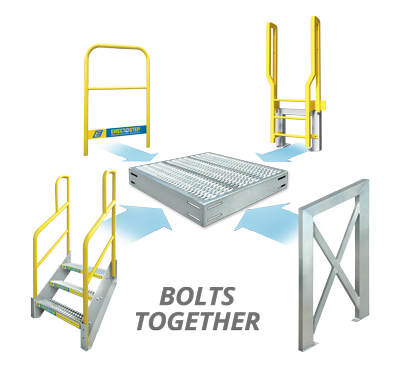

Five modular components allow endless configurations

-

Assemble in a few hours—no welding or cranes required

-

No need for custom fabrication

-

Easily unbolt, reconfigure, and relocate on site

-

Fast quotes, drawings, and rapid installation

-

In stock and ready to ship from our warehouse

Custom Stair, Ladder & Platform Configurations Available

ErectaStep crossover stairs are built from five modular parts. With these five pieces, you can configure an infinite number of fall protection and worker access systems without drilling, cutting, or welding. All of the components share bolt hole patterns, reducing overall part count, and streamlining the assembly process. Simple hand tools are all that’s needed to attach the handrails, stairs, or ladders to a work platform side. You can unbolt and re-purpose or expand an ErectaStep system at any time. Some of these configurations include rooftop crossover stairs, conveyor crossover stairs, and crossover ladders and platforms.

Sample ErectaStep Configurations

3-Step Industrial Crossover

6-Step Industrial Crossover

Low Access Work Platform

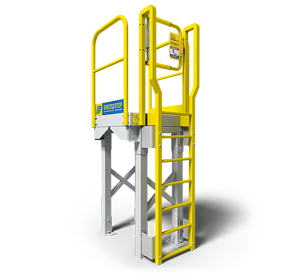

Multilevel Step Platform with Ladder

6-Step Industrial Ladder Platform

Assembly Line Crossover System

Catwalk Crossover Ladder

Industrial Mezzanine Access System

Modular Platforms and Stairs

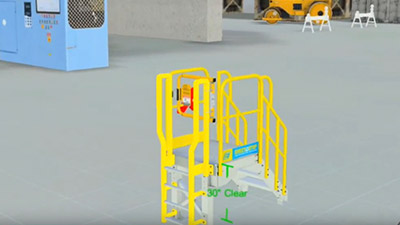

With ErectaStep, three platforms can be bolted together in a series without tower supports, providing up to 9′ of walking surface. Need additional clearance? Simply add extra platforms with bolts and tower supports to reach the length and width you require.

ErectaStep’s modular components enable users to combine stairs, ladders, and platforms at almost any height to accommodate unique space dimensions and satisfy worker access needs.

Fast, Detailed Quotes Available

ErectaStep is a modular, pre-engineered, OSHA-compliant solution that is ready for immediate shipment. ErectaStep design and configuration is done with an app and oftentimes takes only minutes. Assembly is fast (depending on size and configuration); some stairs are ready to go within four hours or less.

To design an ErectaStep industrial crossover stair solution, you simply measure your required height and length clearance and then contact us. Our experienced customer service representatives are ready to help you with sizes and other specifications. With this information, we can provide a detailed quote complete with engineering drawings in just a few hours.

Rapid Industrial Stairs and Platforms Installation Services

In a matter of hours, most ErectaStep configurations can be assembled on-site. Banks Industrial Group also offers installation services so that your staff can focus on other tasks.

Precision Manufacturing in the U.S.A.

All ErectaStep components are robotic laser-cut and welded at the factory. Platforms and stairs are stamped for the highest strength and accuracy available. Component specifications are available.

Fulfillment Center Conveyor Crossover Bridge Case Study

BIG improved efficiency in a busy distribution center by installing an ErectaStep crossover bridge system to provide safe and easy access over conveyor belts. Learn more about it here.

Applications for ErectaStep modular work platforms are as numerous as their potential configurations. Some examples include raised industrial walkway, gas pump station crossover stairs, generator access stairs and work platform, rooftop crossover stairs, conveyor crossover stairs, and crossover ladders and platforms.

For more examples, click here.

Curious about prices? Learn about crossover installation costs. Interested in safety? Learn more about safety compliance and OSHA 1910 codes.

Related Safe Access Equipment

Need an Industrial Crossover Stair Solution? Contact Banks Industrial Group Today

Banks Industrial Group is your source for industrial crossover stair systems. Offering onsite consultation with immediate, on-the-spot quotations for stair, ladder, and access platform configurations, Banks Industrial Group can design your ideal solution within minutes and install in a matter of hours.

Banks Industrial Group specializes in above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative, and cost-saving solutions help keep your facility running efficiently. For more information about our industrial crossover stairs, contact our team today by calling 856-687-2227.

How does ErectaStep arrive to my worksite? Do I need a crane to put them on a roof?

- ErectaStep components will arrive flat-packed on pallets complete with a tool kit required for installation.

- No need for a crane for rooftop applications. If one is available, it will be helpful, but each component can be broken down to be carried to a roof by one or two technicians on stairs or via service elevator.

Can my workers install and build ErectaStep? What tools are needed?

Yes. Most crossovers can be installed by two technicians, one socket wrench and two different length bolts.

Do the platforms need to be anchored? How to anchor ErectaStep?

- Yes. 2 bolts per footing is required for platforms under 6 steps and 4 bolts per footing is required for 6 or more steps.

- The depth of the anchor, the size of bolts and the type of bolts should be determined by examining ambient conditions (indoor, outdoor, etc), the depth and area of the concrete base and the size of the platform. Generally, the larger/higher platforms will require longer or sturdier anchors. Anchors should be 5" or longer and should be absolutely no closer than 4" from the closest concrete edge to avoid cracking the concrete. For outdoor applications, you should choose a galvanized anchor. For indoor, you could choose galvanized, zinc plated or stainless anchors.

- ErectaStep also makes a Stair and Tower Concrete Form Kit available for sale that provides the base and anchors. Add concrete to the form and its done.

Are the handrails easily mounted?

Yes. Handrail mounting can be installed with only 4 bolts.

Can I modify my ErectaStep system after purchase?

Yes! That is the genius of using a modular system. You can also repurpose it later if your requirements change or if your floor layout changes.

If my factory floor changes, can I reuse this system?

Yes.

What is the issue with having our workers fabricate a set of stairs?

Businesses with the resources can absolutely have their own people fabricate stairs. However, they should weigh the cost of compliance into that equation. Will a homemade solution be compliant with the numerous regulations set forth by OSHA or IBC-codes?

How do I know that the product is OSHA compliant?

You can look at our diagrams here: ErectaStep OSHA Compliant Features.

Will this product meet our building code?

Depends, as all states have different codes. Ask us and we will help you determine the answer.

Can you provide an engineering stamp for ErectaStep?

Yes, ask us and we can arrange to have stamped drawings by a licensed engineer for your state.

Are ErectaStep products CA-65 compliant?

The yellow powder coating used by ErectaStep (manufactured by Sherwin Williams) for handrails and toe boards is non-compliant to CA-65.

Are these products ADA compliant?

No, they are not.

What is the cost of a crossover?

- The cost of a crossover starts with a few questions. Does your crossover need stairs or ladders? What is the walking height or clearance required? How far does it need to span?

- Erectastep varies in cost depending on the combinations of products used, but the stair components average about $596 per step while ladders average about $628 per ladder rung. Each stair or ladder rung has a rise of 9”, so you can figure out the walking height required with some simple math. Finally, the span of the crossover matters too – each walking platform comes in 3-foot increments and typically is flanked by two handrails. The cost of each platform with handrails will average about $598 per linear foot.

- For example, a four-step stair crossover with a single platform and handrails in the middle should cost:

- Left stair = 4 * $596 = $2,384

- Right stair = 4 * $596 = $2,384

- 3-foot platform plus handrails = 3 * $598 = $1,794

- Total = $6,563 plus applicable shipping and/or sales tax

How long does it take to produce a quote?

Depending on the complexity of the requirement, a rep will typically have engineered drawings and a quote to you in less than a day, sometimes in less than an hour for simple platforms. “Standard” configurations can take as little as 30 minutes. More complicated ones a day or more.

What is the lead time for standard products?

- We can usually ship standard products on the same or next day.

- Custom orders typically take 6-8 weeks after the completion and acceptance of drawings.

What is the maximum height an ErectaStep platform can go to and what’s the longest span without a support the platform can go?

- ErectaStep can rise 15 steps before a landing is required to meet OSHA codes (every 12' of vertical rise).

- A standard off-the-shelf product can go up to 20 steps, or a walking height of 15'. Custom supports can be designed for higher.

- 9' or 3' platforms is the longest span.

What clearance does each crossover provide?

- To determine the clearance, multiply the number of steps times 9", then add 3" to that result.

- 6" tall gussets mounted on the underside of either end of the platform will reduce clearance available. The impact of that reduction depends on the size of the barrier requiring clearance.

- We make available a clearance diagram to help size crossovers. You can request a PDF download here, and we will email it to you.

How high is the top of the walk surface?

To determine the height of the walking surface, multiply the number of steps times 9", then add 9" to that result.

What is the weight rating of each platform?

50 lbs per square foot or 450 lbs distributed load per platform; a custom order can provide up to 100 lbs per square foot.

What is the rise and run of the stair units?

9" rise, 9.5" run for all OSHA-compliant systems.

How wide are the stair treads?

Each stair tread is 26" wide and each stair measures 30" from the outside edges of each handrail.

Do you have removable handrails?

Yes!

What finishes are available? Can it be made in steel?

- Powder coated aluminum or mill-finished aluminum.

- Mill-finished aluminum parts that are normally powder coated can be special-ordered.

- Yes, we can custom order the same product in steel.

Are diamond plated platforms available?

Yes.

How heavy are these products?

Each component is so light that two adults can carry any single product from the loading dock to the install site or upstairs to a roof. More information on weight can be found on our ErectaStep Components page.

Is ErectaStep made in the USA?

Yes, each part is manufactured in South Carolina.