Techna-Duc HVAC Ductwork Insulation Case Studies: Commercial and Industrial Facilities

Replacing Failed Commercial/Industrial HVAC Ductwork Insulation Improves Energy Efficiency and Reduces Usage Hours

Commercial HVAC Ductwork Insulation Case Study: Replacing Compromised Ductwork Insulation to Improve Performance and Reduce Energy Costs

Building Specs:

Multi-Floor Commercial Facility Owned by The Pennsylvania Housing Finance Agency (PHFA)

Pain Point:

Damaged HVAC System Due to Poorly Insulated Ductwork

Pennsylvania Housing Finance Agency’s Vision:

On behalf of the Pennsylvania legislature, the PHFA provides affordable homes and apartments for older persons, adults of modest means, and those with special housing needs.

Pennsylvania Housing Finance Agency’s Challenge:

The rooftop HVAC system installed in PHFA’s multi-floor main office became compromised due to environmental conditions and poor insulation. Five years after installation, the system became rusted, water-logged, and infested with mold and mildew.

The Challenge’s Impact on PHFA’s Day-to-Day Work:

The damaged HVAC system threatened the health of PHFA’s workers and increased energy costs. The mold and mildew within the ductwork had the potential to create hazardous air problems throughout the entire building. The HVAC system’s poorly insulated duct joints also led to higher energy bills for the agency, driving up operating costs.

To protect workers' health and keep operating costs manageable, PHFA needed a quick solution to their ductwork problem.

Banks Industrial Group’s PHFA Solution: Techna-Duc® HVAC Ductwork Insulation

Banks Industrial Group solved PHFA’s challenge by replacing their failed insulation system with a new system from Techna-Duc®. The Techna-Duc® system was the perfect long-term solution for PHFA’s problem due to its:

- R-16 installed thermal value (166% higher than R-6)

- Mold- and mildew-resistant properties

- Triple-sealed, water-tight interlocking joint system

- Minimal maintenance needs

Techna-Duc® systems are pre-manufactured insulated panel systems. All of the panels are constructed with polyisocyanurate insulation to prevent the growth of mold and mildew. The panels’ water-tight qualities also prevent the ingress of water and water vapor, practically eliminating air quality problems.

By replacing PHFA’s compromised ductwork with a Techna-Duc® system, BIG helped PHFA:

- Protect the health of its employees by eradicating air quality problems

- Eliminate maintenance needs

- Save tens of thousands of dollars in yearly operating costs

- Reduce necessary system cooling time

See the chart below for an in-depth look at how the Techna-Duc® system is saving PHFA substantial money year-after-year:

|

Initial Cost Difference to Install Techna-Duc |

$37,678 |

|

Estimated Savings after Installation |

$30,000/yr |

|

Return on Investment in Years |

1.3 Years |

|

Savings Over 20 Year Limited Warranty |

$599,920 |

|

Annual Tax Base Not Required due to Energy Savings |

$299,957 |

|

20 Years of Tax Base Not Required |

$5,999,140 |

|

20 Years of $0 Maintenance ($5,000 / year) |

$100,000 |

|

4 Replacements of Original System ($110,000 each) |

$440,000 |

|

Total Savings Over 20 Years |

$7,139,060 |

Techna-Duc® Multi-Floor Commercial Building Case Study

Is this what is on your roof? How much does this cost you?

Original Insulation System

- Fiberglass Insulation

- Field Fabricated

- Thin Jacket (.016” Thickness)

- Rivet Fasteners

- Regular Maintenance Required

- Susceptible to Moisture Intrusion

- R-6 Installed Thermal Value

- 1 Year Contractor Warranty

Are you ready for the solution?

Techna-Duc® Insulation System

- Shop Fabricated

- No Maintenance Required

- Interlocking Joint System

- Water Tight Triple Sealed

- Extremely Durable

- > 20% Energy Savings

- R-16 Installed Thermal Value — 166% Higher Than R-6

- 20 Year Limited Warranty

For more information about our HVAC ductwork insulation, and other industrial solutions, contact our team today by calling 856-687-2227.

Industrial HVAC Ductwork Insulation Case Study: Replacing Water-Logged Ductwork Insulation to Resume Manufacturing Facility Operations

Building Specs:

Large Manufacturing Facility

Pain Point:

Damaged Rooftop Exterior Ductwork

Manufacturing Facility’s Vision:

Maximize operational productivity day-in and day-out

Manufacturing Facility’s Challenge:

The facility’s fiberglass-insulated aluminum rooftop ductwork was failing due to excessive moisture and construction defects.

The facility operators installed the ductwork four years before contacting BIG. The operators initially considered installing a Techna-Duc® system but opted for a fiberglass-insulated aluminum system instead to save $5000.

Within a year of installation, facility workers discovered that rainwater was leaking through the system’s jacketing seams and protrusions. The leaks reduced the insulation's performance value, increasing the facility’s energy costs. By this point, the wet insulation caused the system to operate worse than if there was no insulation at all.

Unfortunately, budget constraints prevented the facility from removing and replacing the water-clogged ductwork until the problem couldn’t be ignored any longer.

The Challenge’s Impact on the Manufacturing Facility’s Day-to-Day Work:

Four years after the aluminum ductwork was installed, the HVAC unit shut down due to excessive moisture in the air system. The resulting downtime cost the facility $80,000 per day in lost production.

Banks Industrial Group’s Manufacturing Facility Solution: Techna-Duc® HVAC Ductwork Insulation

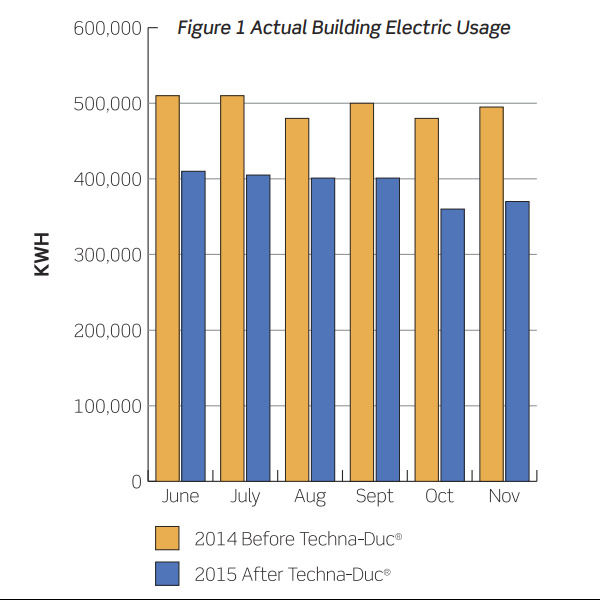

BIG ended the facility’s extended downtime period by removing the water-logged insulation and replacing it with a water-tight Techna-Duc® system. With 12,600 square feet of Techna-Duc® installed, the facility was able to resume operations and experience the following energy savings:

- 105,000 kW/hrs saved monthly

- At $0.11/kwh = $11,500 monthly

- Annual savings = $136,000

- 20 Year ROI = $2.72 million projected

For a visual breakdown of the facility’s monthly energy savings, see the chart to the side.

In addition to reducing energy needs, the facility experienced additional savings by:

- Decreasing HVAC unit runtime

- Preventing HVAC unit shutdowns

- Eliminating maintenance and equipment replacement costs

Looking forward, the facility’s Techna-Duc® system is also protected by a 20-year limited warranty, ensuring that the facility won’t require another system replacement for at least two more decades.

Techna-Duc® Manufacturing Facility Case Study

Failure • Loses Money

Original Insulation System

- Field Fabricated

- Thin Jacket (.016” Thickness)

- Rivet Fasteners

- Regular Maintenance Required

- Susceptible to Moisture Intrusion

- R-6 Installed Thermal Value

- 1 Year Contractor Warranty

20 Year Warranty • $2.72M in energy savings

Techna-Duc® Insulation System

- Shop Fabricated

- No Maintenance Required

- Interlocking Joint System

- Water Tight Triple Sealed

- Extremely Durable

- > 20% Energy Savings

- R-16 Installed Thermal Value — 166% Higher Than R-6

- 20 Year Limited Warranty

Banks Industrial Group specializes in above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative, and cost-saving solutions help keep your facility running efficiently. For more information about our HVAC ductwork insulation, and other industrial solutions, contact our team today by calling 856-687-2227.