Wastewater Treatment Coating & Repair Solutions

Banks Industrial Group provides protective coating and repair service for wastewater treatment equipment and structures operating in rough environments. Our solutions fix problems caused by erosion, corrosion, abrasion and chemical attack. Repairs and coatings are long-lasting and will lower maintenance costs by extending asset service life. Click or tap your problem area on the map below to see how we can solve it.

Before

After

Pipe Coating

Pipe coatings can improve the efficiency of new pipes, restore lost structural integrity of a deteriorating pipe, and prevent future corrosion of the substrate. Our coatings provide long-term corrosion protection with excellent chemical resistance. Learn more about polymeric coatings.

Joint Sealing, Hole Sealing & Structural Repair

Banks Industrial Group provides various protective linings as solutions to issues in deteriorating pipes, however it’s important to keep in mind that linings do not stop existing infiltration. We provide expert installation of polyurethane and epoxy systems to suit the specific requirements of your structure. Learn more about our Concrete Leak Injection services.

Before

After

Infiltration & Exfiltration Prevention

Groundwater infiltration and exfiltration is a common problem encountered by municipalities, especially those with aging infrastructure. The #ThinkBIG solution to preventing infiltration uses chemical grouting to seal up cracks and voids in the infrastructure thus leaving the system as effective or more effective than it was previously. Learn more about our grout injection services >>

Before

After

Groundwater Penetration Prevention

Optional Subhead Goes Here

Short text goes here.

Learn more about groundwater penetration prevention >>

Before

After

Lift Station Maintenance & Repair

BIG can restore heavily damaged pumps to their original profile by using cold-curing metal repair composites. The BIG team will evaluate each job for cause of damage to pumps and pipes to better provide a long-lasting solution specific to your needs. Learn more about our polymeric pump restoration and protective coating services.

Before

After

Headworks Repairs

Bar screens, grit separators, grit pumps, conveyors and pipe work are exposed to constant wear from abrasives, erosion and chemical attack. BIG provides a wide variety of polymeric repair compounds and coatings to rebuild and protect damaged metal and concrete equipment and structures. Materials are fast curing and can often be applied in-situ to avoid or minimize downtime.

Learn more about our polymeric repair and coating services >>

Before

After

Screw Conveyor Repair & Protection

BIG takes care of screw conveyors damaged from abrasion, corrosion and erosion. Our abrasive resistant materials rebuild lost metal on flights and shafts and protect against future damage. Application is fast and does not require hot work. Save money by rebuilding equipment, restoring lost efficiency and extending time between maintenance intervals.

Before

After

Shaft & Bearing Repair

Shafts, keyways, bearings and agitator blades eventually become worn and damaged from repetitive motion and abrasive conditions. Conventional repairs are often expensive and require drawn-out downtime. Fortunately, BIG provides an easy, in-situ repair of shafts, keyways and metal components. Our polymeric metal rebuild compounds are rapidly applied without the need for lengthy downtime or welding. Repairs are durable and cost-effective.

Learn more about BIG shaft repair service >>

Before

After

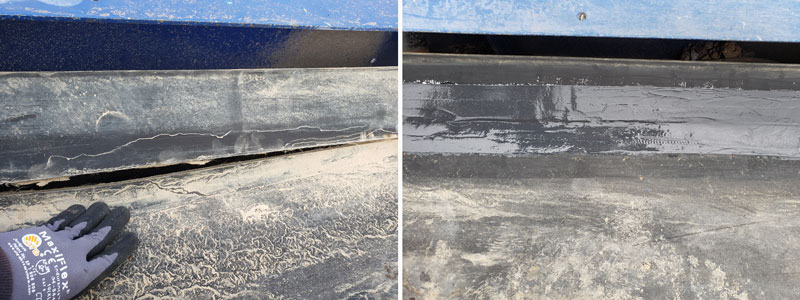

Expansion Joint Sealing & Repair

BIG provides specialized expansion joint repair and sealing for wastewater treatment applications. Our polymeric solutions are quickly applied and give you long-lasting results that withstand expansion movements, abrasion and chemical attack.

Learn more about expansion joint rebuild and sealing >>

Before

After

Concrete Repair for Steps & Walkways

Banks Industrial Group handles a wide variety of concrete repair needs that can arise at industrial facilities. Our experienced crews will evaluate areas of damage and recommend the best repair method and materials for your needs.

Learn more about our concrete repair services >>

Before

After

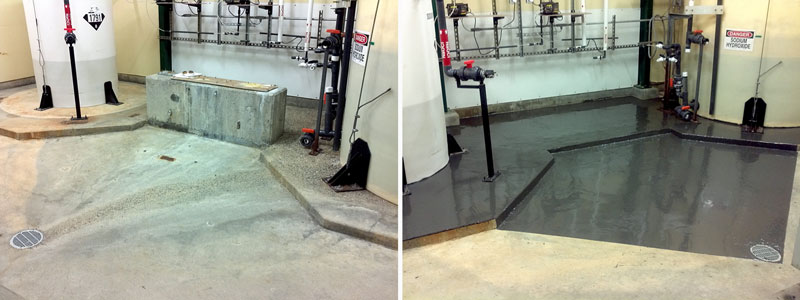

Containment Area Coating & Repair

Avoid Shut Downs & Environmental Fines

Prolong the service life of secondary containment sumps, pits, channels, and bases with a cold curing, solvent-free coating. Containment areas can easily deteriorate due to the extreme stress of operating conditions. By applying a protective coating to the area, you reduce the risk of environmental contamination.

Learn more about containment area repair and protective coating >>

ErectaStep Crossover Stairs

Re-Configurable, Industrial Stair & Work Platforms

ErectaStep allows you to configure an infinite number of fall protection and worker access systems. Handrails, stairs and ladders can attach to common bolt holes on any side, allowing any configuration without drilling or fabrication. Configurations can be altered and components can be re-purposed at any time, and BIG can have units professionally installed upon request.

Learn more about ErectaStep crossover stairs and ladders >>

Before

After

Pipe Wrap Repairs

Wraps and Coatings to Rebuild and Ensure Efficiency

Corroded, weakened or holed pipes do not always require replacement. Banks Industrial Group installs composite repair systems to restore structural integrity, repair leaks, and prevent corrosion. The easy application installs quickly and can reduce downtime with possible online applications.

Learn more about pipe wrap repairs >>

Before

After

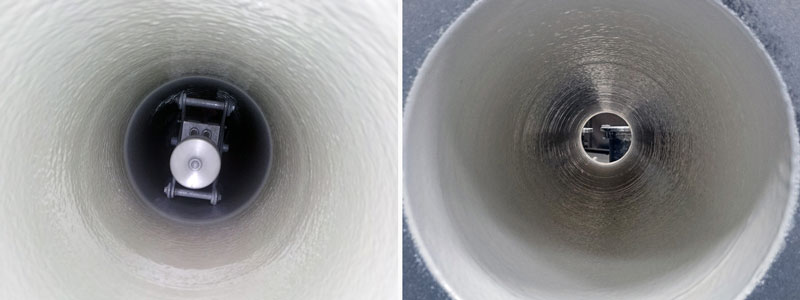

Dewatering Centrifuge Repairs

How many times have worn flights or struvite accumulations ruined your day when a centrifuge shutdown? BIG has a solution that will improve reliability and reduce maintenance cost. Worn flights and delaminated tiles can be rebuilt with tough polymeric materials that resist abrasion and corrosion. We can also apply a protective coating to the centrifuge interior that will reduce struvite scale clogging and extend the interval between service times.

Before

After

Belt Press Conveyor Repair

Save Money By Extending Service Life

BIG has an outstanding elastomeric repair for worn, torn, or ripped conveyor belts. Our solution is applied in-situ without the need of hot work and is extremely durable. Repairs are fast, typically completed in a matter of hours to get your belt press up and running again. Learn more about BIG conveyor belt repair service.

Before

After

Abrasion Resistant Pump Coatings

Pumps experience damage caused by corrosion, erosion, abrasion, impact, and chemical attack, problems that we can prevent with our skilled application of abrasion resistant pump coatings. Use of these protective coatings also improve efficiency and extend the service life of your pumps.

Learn more about pump efficiency improvement >>

Before

After

Pump Corrosion Rebuild & Protective Coatings

Repair, Protect, Improve

BIG can help you avoid expensive replacement and downtime by repairing, restoring and protecting pumps damaged by erosion, corrosion, chemical and abrasive damage with Belzona products.

Learn more about polymeric pump restoration and protective coatings >>

Before

After

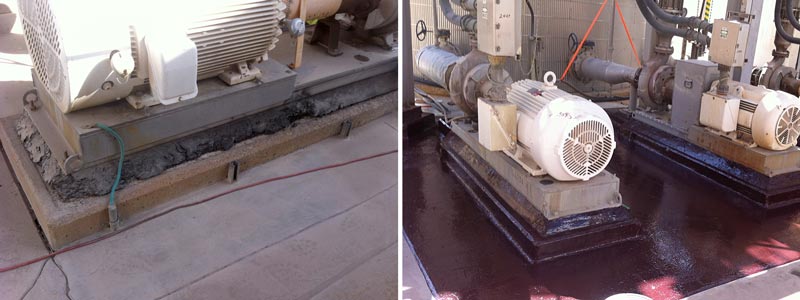

Pump Pedestal Repair

Fast Application, Durable Protection

Repair and protect concrete pump bases and casings from chemical spill with Belzona Magma CR polymers.

Learn more about pump pedestal restoration >>

Before

After

Acid Tile Repair

Our experienced #ThinkBIG team inspect and repair damage to protective linings in process vessels, tanks, chimneys, lagoons, pits and drains. The BIG acid tile rebuild solutions use specialized Belzona tile linings for erosion protection of pipes, screw conveyors, chutes, and hoppers. Replacement materials are carefully matched with those meeting the chemical, heat, and abrasion resistance required by your facility.

Learn more about acid tile repair >>

During

After

Pipeline Protective Coatings

Pipe coatings can improve the efficiency of new pipes, restore lost structural integrity of a deteriorating pipe, and prevent future corrosion of the substrate. Our coatings provide long-term corrosion protection with excellent chemical resistance. Learn more about polymeric coatings.

Before

After

Handrail Reset Grout Repairs

Fast-Curing, Durable

Water easily infiltrates and deteriorates traditional grouting which causes handrails to become wobbly and unsafe. BIG provides fast repair of this problem using polymeric grout for fast-curing, durable, water resistant repairs.

Non-Slip Floor Coating

Durable, Hard Wearing Slip Reduction Systems

BIG offers a range of safety grip systems that create a durable non-slip surface in workshops, industrial and storage facilities, stairs, manufacturing plants, tank roofs, etc.

Learn more about our anti-slip coating service.

Before

After

Tank Corrosion Rebuild/Repair

Increase Service Life & Protect Assets

Reinforce and repair thin-wall and/or through-wall defects in metal structures with composite wraps or steel plates bonded to exterior surfaces using Belzona products – no hot work or welding permits required.

Learn more about our tank repair services >>

Before

After

Tank Coatings & Linings

Protect Assets, Increase Service Life

Drum thickeners and digester tank interiors are exposed to corrosion from chemicals and methane gases that attack the steel substrate. BIG offers protective coating solutions to increase the reliability and service life of assets that may otherwise need replacement or face a shortened service life. Tanks are quickly repaired, coated and placed back into service with minimal downtime. No hot work is required–materials are cold curing for improved safety.

Learn more about protective tank coatings >>

During

After

Tank Base Sealing

Long-term Solution, Flexible & Breathable

Conventional tank base sealing methods such as caulk and mastic sealing tapes are prone to failure. This allows water to infiltrate underneath the tank base where it causes corrosion and risk of leakage. BIG provides a long-term solution that is flexible to accommodate tank movements and breathable to allow trapped moisture to escape. Can be safely applied to tanks that are in service.

Learn more about tank base sealing >>

Before

After

Protective Coatings for Wastewater Tanks

Protect Assets & Increase Service Life

BIG offers industrial coating solutions to increase the reliability and service life of structures and equipment subject to abrasion, erosion, corrosion, and chemical attack. Containment areas, pipes, vessels, tank walls, pumps and heat exchangers that may otherwise need replacement or face a shortened service life, can be quickly repaired, coated and placed back into service.

Learn more about protective tank coatings >>

Before

After

Concrete Substrate Repair

BIG provides concrete repair and coatings that are specifically designed to refurbish and protect sewage systems from common problems such as concrete spalling, wear and chemical attack as a result of hydrogen sulfide, heavy load and erosion. Our cost-effective solutions are rapidly implemented and can extend asset service life for many years.

Learn more about our concrete repair services >>

Before

After

Clarifier Track Repairs

BIG provides fast repair of worn down clarifier running tracks and troughs eroded by water flow and chemical attack. We resurface tracks with durable polymeric material that is impermeable to water and resists abrasion, impact, vibration, chemical/environmental attack. Spalled troughs are repaired then protected with a chemical resistant coating to shield against future damage. Repairs are long-lasting and can be accomplished with minimal downtime.

Learn more about our concrete tank repair services >>