Industrial Grouting Service

Banks Industrial Group (BIG) is your trusted partner for all your industrial grouting needs. With our specialized services, we offer top-notch solutions for machinery mounting, vibration cushioning, equipment foundation rebuilding, and the filling of voids, gaps, cracks, and seams in concrete structures. Our team is well-versed in the latest grouting techniques and utilizes fast-curing materials to ensure a quick turnaround and minimal downtime for your operations.

What sets us apart is our commitment to quality and customer satisfaction. We take the time to understand your specific grouting requirements and tailor our solutions accordingly. Our attention to detail and precision ensure that every void, gap, crack, or seam is expertly filled, providing long-lasting durability and stability for your equipment bases.

Choose Banks Industrial Group for your industrial grouting needs. Our specialized services, experienced crews, and quick turnaround time make us the ideal choice for businesses in need of reliable grouting solutions. Contact us today to discuss your requirements and let us provide you with the exceptional service you deserve.

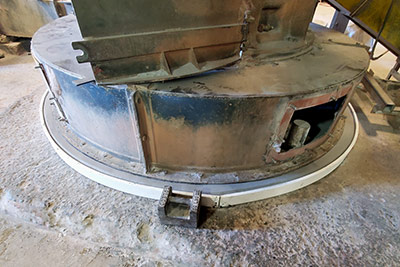

Industrial fan machine base rebuilt with epoxy grout.

Need Industrial Grouting?

Request an estimate or consultation.

| Benefits of BIG’s Industrial Grouting Service | |

| Custom Fit for Your Environment | BIG carefully matches all materials to your exact operating environment. |

| Specialized Grouts for Your Requirements | We use the following specialized grouts:

|

| Industry-Leading Repair and Rebuilding Services | As part of our industrial grouting service, we can:

|

Problem: How to repair concrete pad underneath a pump without service interruption?

Your pump's reliability is compromised by eroded and crumbling concrete equipment pads. Pumps and other reciprocating equipment need solid foundations for dampening vibration and transferring operating stresses into the ground.

Loose baseplate grouting can cause bearings, mechanical seals, and couplings to be damaged. This applies to all pumps but especially to larger horsepower units. Increased maintenance costs and breakdown risks result.

The obvious solution is to replace damaged concrete and/or grout. But what do you do if your equipment must remain operational?

Solution: Minimize downtime by restoring your pump base with fast curing epoxy grout

When it comes to restoring damaged concrete equipment pads and replacing grouting on baseplates, epoxy grouts are the material of choice. Look for grout with a fast cure time to enable speedy repair. You will have minimal downtime with the right grout.

In many cases, restoration takes hours or days instead of weeks for new concrete to cure. Epoxy grout creates a strong adhesive bond between concrete, brick, and steel, ensuring that repairs last long. For pumps, low-shrinkage materials provide the best baseplate bond.

Furthermore, epoxy grouts feature high compressive strength, excellent impact and vibration resistance, and good chemical and water resistance. This makes them perfect for machine base grouting.

For specialized applications, formulations that are resistant to strong acids and thermal shock are available. Choose safe, VOC-free materials that do not require hot work (or hot work permits). This will further speed up the repair process.

Last but not least, consult an expert. For a durable result, selecting and applying the right material correctly is essential. You should carefully consider all aspects of your operating environment.

You can extend the life of your pump by repairing damaged grouting and concrete on the baseplate. Deterioration shouldn't be ignored. The risk of an unplanned shutdown will increase as the damage worsens.

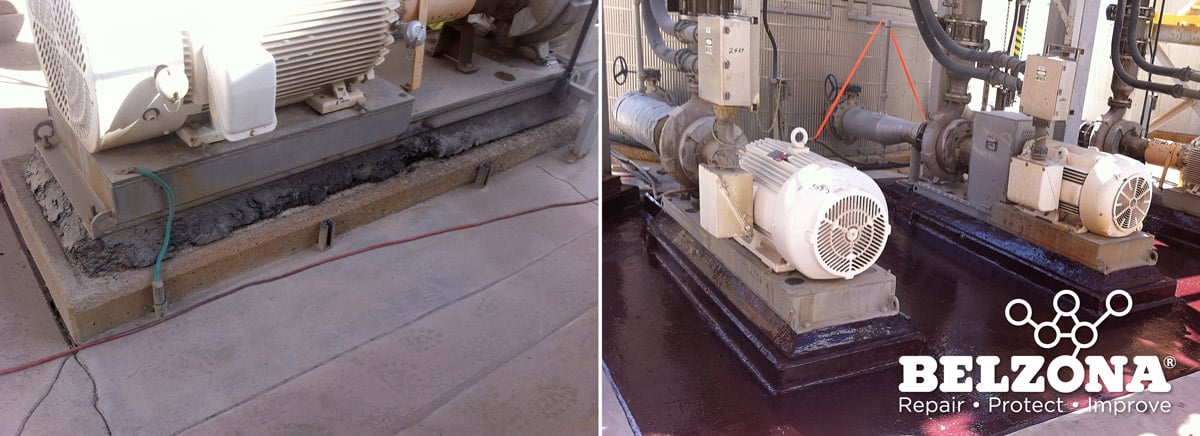

Epoxy grout used to rebuild pump base concrete.

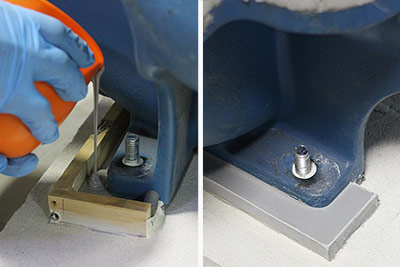

Shim pump baseplate gaps with fast curing, pourable epoxy chocking.

Pulverizer baseplate grout retoration.

How Can We Help You?

Banks Industrial Group specializes in industrial grouting services, above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative and cost-saving solutions help keep your facility running efficiently. For more information about our concrete floor repair and other industrial solutions, contact our team today by calling 856-687-2227.