Portable Stairs

OSHA & IBC Safety Compliant Models

Banks Industrial Group offers portable stair systems from Upside Innovations, crafted in the USA with durable industrial-grade aluminum. These stairs resist rust, warping, and rot, providing a secure walking surface that meets OSHA or optional IBC safety standards. Field-adjustable for uneven terrain, they offer stability and easy re-positioning. Most units are in stock at our Philadelphia area distribution center.

Features We Like

-

Pre-engineered OSHA and optional IBC compliant models

-

Non-slip decking and steps keep employees and pedestrians safe from slips and falls

-

Heavy-duty industrial aluminum that will not rust, warp or rot

-

Height adjustable models for easy leveling on uneven surfaces

-

Fast assembly – bolts together with simple hand tools, no welding required

Models Available

-

Office Trailer Steps – lightweight and highly adaptable, aluminum Omni Steps adjust to different work site terrain

-

Loading Dock Steps – built to last with heavy-duty aluminum construction, Dock Steps are ideal for warehouses and distribution centers

-

Semi-Trailer Steps – lightweight, aluminum Semi Steps provide non-slip access for workers entering semi-trailer containers

Need Portable Stairs?

Request an estimate or consultation.

Portable Stairs for Mobile Office Trailers

Omni Step portable stairs improve accessibility to mobile offices and construction trailers by offering versatility across different terrains. With adjustable legs and pivoting risers, they make leveling on uneven ground a breeze. These prefabricated stairs are designed for quick assembly, making them perfect for workspaces that are frequently relocated.

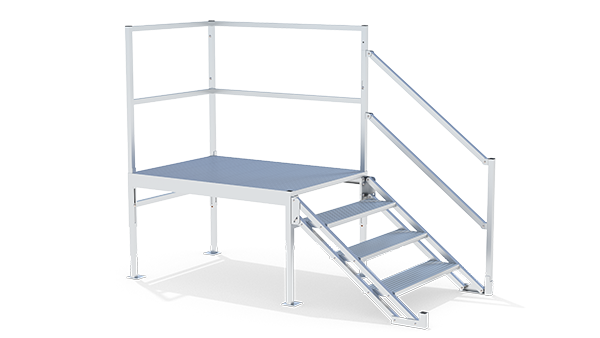

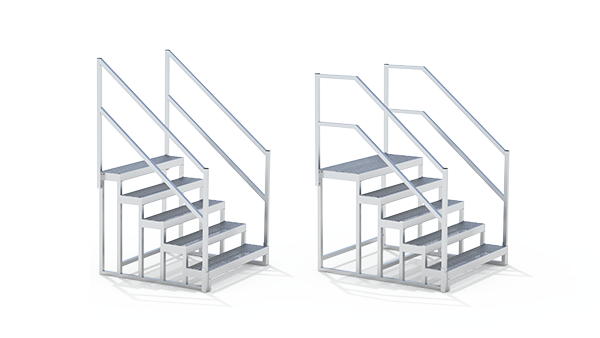

Loading Dock Stairs

Banks Industrial Group offers durable, OSHA- and optional IBC-compliant aluminum loading dock stairs for safe warehouse access. These corrosion-resistant stairs are designed with pre-fabricated components, a 9" vertical adjustment, and choice of guardrails and handrails, making them perfect for a range of loading areas and uneven surfaces.

Portable Semi-Trailer Steps

BIG offers portable, lightweight aluminum stairs for safe, non-slip access to semi-trailers. Constructed from durable aluminum, these stairs outperform plastic and steel counterparts, offering rust resistance for long-lasting durability and effortless portability on job sites.

Banks Industrial Group is your source for portable stairs. Whether you need to safe access to a mobile office trailer, loading dock, semi-trailer, warehouse or similar work location, BIG has a solution to match the application. Most stairs are in stock and ship from our Philadelphia metro area distribution center.

Banks Industrial Group excels in providing thermal insulation, protective coating, concrete services, and other industrial maintenance and repair solutions. We offer innovative and budget-friendly solutions designed to reduce downtime and ensure your facility operates smoothly. To learn more about our portable stair solutions, we invite you to reach out to our team by calling 856-687-2227 today.

Are you wondering how to distinguish between OSHA and IBC stair requirements?

We have created an illustrated blog post that explains the differences and requirements of each type. Read here to gain a better understanding of this puzzling topic.