Conveyor Belt Rip Repair Service

Fast, Durable Solutions To Extend Asset Service Life

Banks Industrial Group fixes ripped, torn and punctured conveyor belts using cold-applied, cold-cure Belzona elastomers. Conveyor belt repair work is done very fast to minimize downtime and keep your material handling system productive. We provide an effective alternative to vulcanization techniques that may not be possible due to time, space and safety constraints.

Applications:

-

Rapid, cold-curing repair of worn, split or torn areas of rubber

-

Repair and encapsulation of clip joints on conveyor belts

-

Rebuild and bond conveyor belt flights and cleats

Benefits:

-

Emergency repairs are done very fast for minimal downtime

-

Exceptional protection against wear, impact and abrasion

-

High elasticity that will return to original shape after stretching, compression or torsion

-

Tenacious adhesion to natural rubber, nitrile, neoprene, SBR (Styrene Butadiene Rubber), polyurethane, PVC, steel, copper and concrete

-

No hot work is required – materials are cold applied and cold curing

-

Solvent free materials reduce health and safety risks

Need Conveyor Belt Repair?

Request an estimate or consultation.

Problem: Traditional Vulcanization Repair Not Possible

Vulcanization repairs require specialized equipment using metal plates to apply heat and pressure to restore rubber components by making a strong chemical bond. This type equipment is time-consuming to set up and difficult to fit in cramped or elevated spaces. It also requires an operating environment where the use of heat and chemicals is permitted. This is often impractical for conveyor belt repair in outdoor coal, ore, aggregate, sand and biowaste material handling settings.

Vulcanization disadvantages:- Specialized equipment is difficult to fit

- Time-consuming to set up

- Requires an environment where hot work is permitted

- Downtime for repairs is longer than Belzona conveyor belt repair

Solution: Cold-Cure Belzona Conveyor Belt Repair

Banks Industrial Group uses Belzona elastomers as an alternative solution for the repair of damaged conveyor belt rips, tears and holes. Belzona rubber repairs are done in situ without specialized tools. They are cold-applied and cold-curing thus eliminating the need for hot work and associated safety risks. A rapid return to service with minimal downtime is possible because the materials are fast curing. Typical repairs are done and ready for service in a few hours. Final results are durable and elastic, providing good abrasion and tear resistance.

Belzona elastomer advantages:- Fast curing for rapid repairs and minimal downtime

- Safe, cold cure materials - no hot work required

- Outstanding abrasion and tear resistance

- High elasticity

- Exceptional mechanical strength

Our skilled field crews can perform repair work at your facility or we can train and equip your staff with Belzona emergency rubber repair kits to do the work yourself – contact us today for more information on availability.

How To Repair A Conveyor Belt With Belzona

Watch a short video demonstration showing how Belzona 2311 is used to repair a conveyor belt.

Other Rubber Repair Problems We Solve Include:

Repair work on damaged dredge hoses.

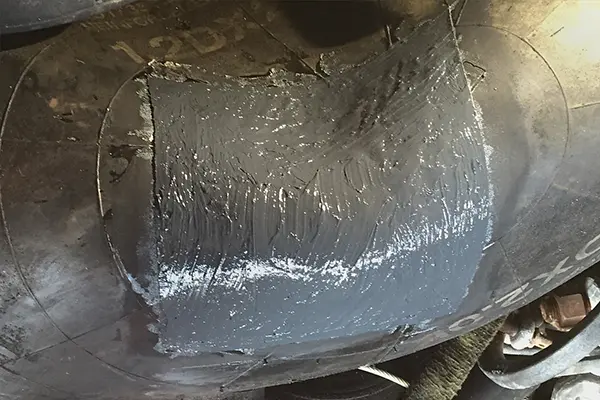

Rapid rubber repair patch on floating hose.

Floating Hose Rubber Repair

Banks Industrial Group provides emergency repair of rubber coatings on floating hoses. Our specialized Belzona elastomeric materials cold-cure in hours for very fast return to service with minimal downtime. Repairs provide long-term abrasion resistance.

Ripped marine fender.

Elastomeric patch used to fix marine fender.

Marine Fender Rubber Repair

Banks Industrial Group provides specialized rubber repair service to fix ripped, torn and punctured marine fenders. We use premium Belzona elastomeric materials to extend the service life of your dock bumpers. Patches are abrasion resistant, bond tenaciously and remain flexible.

Pump volute eroded by abrasive materials.

Elastomeric lining protects pump volute.

Pump Abrasive Protective Lining

Banks Industrial Group provides specialized elastomeric lining service to shield pump volutes and impellers against heavy-duty abrasive operating conditions. Our premium Belzona materials give pumps durable protection against extreme wear, impacts and cavitation.

Banks Industrial Group is Philadelphia's Source for Cold-Cure Conveyor Belt Repair Service

Banks Industrial Group provides elastomeric conveyor belt repair services. We are safety-oriented, ISNetworld certified A+, and fully insured to reduce your risk.

Banks Industrial provides torn conveyor belt repair services for warehouse and industrial material handling applications. We understand the high cost of downtime and work diligently to apply an effective, long-lasting repair with a fast return to service. For more information about rubber repair and our other industrial solutions, contact our team today by calling 856-687-2227.