Centrifugal Pump Repair

Corroded, eroded, or worn pump components don’t always need replacing. Banks Industrial Group offers expert pump repair services using Belzona metal restoration systems—designed to rebuild and reinforce impellers, volutes, vanes, and more. Our cold-applied repairs restore original geometry, eliminate surface defects, and protect against future damage—without welding or extended downtime. Whether you're battling wall loss, pitting, or mechanical wear, our fast, safe, and cost-effective solutions help extend pump life, reduce maintenance costs, and keep your operation running at full capacity.

What We Like About Belzona Pump Repair & Coating Epoxies

Proven Belzona pump repair solutions are globally trusted to restore components damaged from erosion, corrosion, abrasion, and chemical attack.

-

Rebuilds Instead of Replacements: Restore damaged components to like-new condition without the cost or lead time of ordering new parts

-

Cold-Applied, No Hot Work: Belzona metal repair systems cure at room temperature—no welding, permits, or fire risk required

-

Restore Critical Tolerances: Machinable epoxy pastes rebuild lost metal and restore fit and function for OEM-like performance

-

Protect Against Future Erosion & Corrosion: Reinforce vulnerable surfaces with ceramic-filled pump coatings to prevent repeat damage and extend service life

-

Faster Turnaround Than OEM Alternatives: Most repairs completed in days—not weeks—minimizing equipment downtime and lost production

-

Works on Complex Geometries: Ideal for impellers, volutes, casings, pump bowls, diffusers, vanes, cutwaters, bearing seats and other components with curved or irregular shapes

-

High-Performance Materials, Field-Proven Results: Belzona products have a global track record of long-term success in harsh industrial environments

-

Trusted by Leading Industries: Our repair services support clients in water treatment, power generation, chemicals, food & beverage, pharma, and more

Talk to a Pump Repair Specialist

Banks Industrial Group technician prepares split case centrifugal pump for repair work after blasting surfaces to near-white metal.

Why Trust BIG For Belzona Pump Repairs?

Pump service companies and maintenance divisions trust Banks Industrial Group for fast, safe, and responsive Belzona pump repairs that minimize downtime and maximize reliability.

- Tailored, Problem-Solving Approach: BIG collaborates with clients to deliver practical, cost-effective pump repair solutions—never overselling or applying unnecessary fixes

- Proven Belzona Expertise: We use high-performance Belzona materials to deliver repairs that are as strong as (or stronger than) metal, extending equipment life, and protecting your investment

- Speed Without Compromise: Our cold-applied, fast-curing techniques minimize downtime, with most repairs completed in just days—not weeks—keeping your operation running

- Versatile Repairs for Complex Needs: From severe pump corrosion and erosion to abrasive and chemical attack, BIG brings the right materials and in-house expertise to tackle the toughest repair challenges

- Safety You Can Trust: With 100% of our team OSHA 30 certified and top-tier ISNetworld safety ratings, BIG ensures every job is done safely

- Offer value-added service to your clients by recommending an expert repair solution that enhances system longevity

BIG Pump Repair Examples

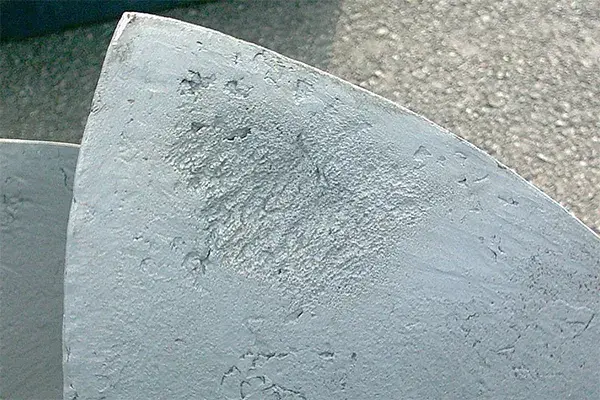

Corrosion and erosion damage causes pump efficiency loss.

Grit blasting surface prep reveals the extent of metal loss.

Areas of metal loss are filled and profiled with Belzona 1111 Super Metal paste.

Pump repair is finished with a protective coating of Belzona 1321 Ceramic-S-Metal.

We Repair Pump Corrosion & Erosion Damage

This axial flow pump experienced efficiency loss due to erosion and corrosion. To restore performance, the pump body and impeller were grit blasted to near-white metal. Areas with metal loss were rebuilt using Belzona 1111 Super Metal paste, followed by two coats of Belzona 1321 Ceramic S Metal coating for long-term protection against future erosion.

Before: Cavitation damage shown on pump impeller vane.

After: Cavitation metal loss is filled with Belzona 1111 epoxy paste.

Pump Impeller Vane Cavitation Repair

Cavitation thinned the vanes on this cooling water pump impeller, risking failure. Belzona 1311 Ceramic R-Metal epoxy rebuilt the damage, followed by a 1321 Ceramic S-Metal protective coating. The repair reduced power use and improved flow.

Before: Erosion damage discovered on water pump volute.

After: Erosion is repaired and protective coating applied to extend service life.

Split Case Drinking Water Pump Volute Repair

The pump owner faced severe erosion and corrosion, with pitting every two years and previous coatings failing within a year. Switching to Belzona cut re-coating to every five years, delivering a durable, cost-effective solution.

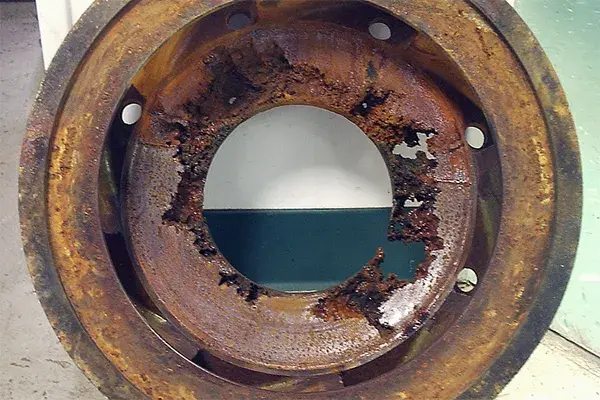

Before: Chemical attack has caused severe corrosion of pump housing.

After: Belzona 1321 Ceramic S-Metal coating protects against chemical attack.

Industrial Wastewater Pump Rebuild

A chemical plant’s wastewater pump suffered severe corrosion, causing pitting, performance loss, and frequent replacements. Belzona 1111 rebuilt the damage, and Belzona 1321 provided lasting protection. Two years later, the pump runs reliably, avoiding costly replacements.

Before: Extreme cavitation damage to a pump diffuser causes performance loss.

After: Belzona 1111 is used to rebuild lost metal and quickly return pump to service.

Cavitated Pump Diffuser Restored With Belzona

A pond pump with significant cavitation damage to the impeller and diffuser was performing below requirements. Lost metal in the diffuser was restored using Belzona 1111 and reinforcing metal rod. After machining the part back to its original dimensions, the pump was returned to reliable service.

Before: Badly worn cutwater and hole through volute.

After: Pump components coated with Belzona 1391 high temperature coating.

Food Processing Condensate Pump Restoration

A customer needed to rebuild a severely eroded back plate and volute and coat a new impeller on a 176°F condensate pump. Since welding cast iron is difficult, we used Belzona to restore the damage without distortion and applied Belzona 1391 for long-lasting, high-temperature protection.

Before: Hole and metal loss in wastewater pump volute casing.

After: Belzona 1111 epoxy metal repair is used to fill areas of metal loss.

Wastewater Pump Repair

A hole in the volute caused wastewater leakage, revealing severe erosion at the cutwater, throat, and flange face. Belzona 1111 rebuilt the damage, and Belzona 1321 coating was applied for wear protection—at far less cost than pump replacement.

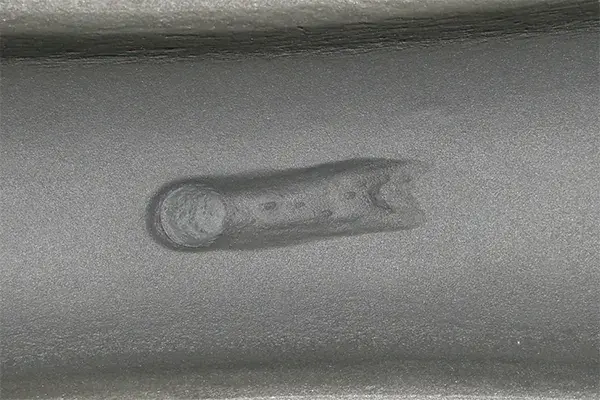

Emergency lift station pump repair in progress on site.

Surface-tolerant Belzona 1212 repair epoxy seals the leak.

Emergency Lift Station Pump Repair

A lift station pump developed a hole beneath the impeller from debris buildup, leaking wastewater into a vault. With limited access, the crew hand-applied surface-tolerant Belzona 1212 after minimal prep. No machining was needed, and the pump was back in service the same day.

Before: Pump bowl and impeller showing cavitation damage.

After: Five impellers restored and coated with Belzona 1341.

Irrigation Pump Refurbishment

This 40-year-old, 5-stage irrigation pump was losing productivity. After grit blasting, areas of pitting and cavitation were repaired with Belzona epoxy, followed by two coats of Belzona 1341. The cost-effective restoration ensures years of reliable service

Areas of metal loss on a large municipal water pump are repaired with Belzona.

Belzona protective coating is applied to prevent wear and extend service life.

Pumping Station Centrifugal Pump Refurbishment

This large centrifugal pump at a Delaware pumping station was refurbished on site. We used Belzona 1111 Super Metal paste to repair minor metal loss and applied a protective Belzona coating to improve efficiency and extend the pump’s service life by protecting the volute from future wear.

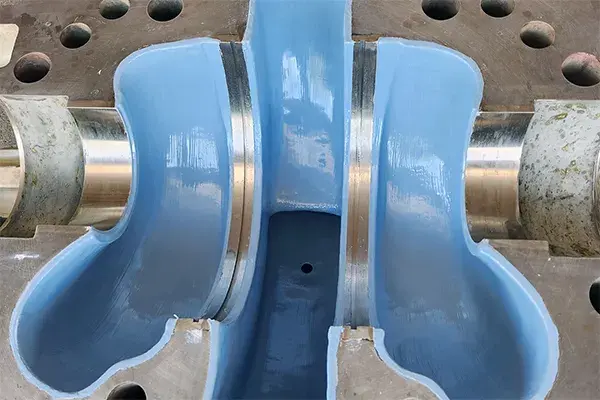

Severe metal loss on cutwater.

Reinforcing mesh is applied.

First coat of gray Belzona 1341.

Final coat of blue Belzona 1341.

Severe Metal Loss Rebuild

After years of operation, this split case pump housing was severely damaged and deemed ready for scrap due to extreme wear on the cutwater, flow straightener, and wear ring seats. Belzona 1311 with reinforcing mesh was used to fully rebuild the damaged areas. Ring seats and gland housings were restored using a precise forming technique, followed by application of a protective Belzona 1341 coating. Instead of paying $50k for a new pump, this cost-effective Belzona repair provided a reliable, long-term solution—more dependable and affordable than alternative welding or machining options.

Before: Corrosion damage to boiler feed pump casing.

After: Specialized Belzona 1391 high temperature protective coating applied.

High Temp Boiler Feed Pump Repair

After a few months in service, this boiler feed pump showed corrosion and erosion, risking casing failure. After surface prep, Belzona 1391 coating was applied for high-temperature protection. Fifteen months later, it remains in excellent condition with no damage or leaks.

Before: Acid exposure caused pitting in the pump volute and loss of reliability.

After: Belzona 4311 protective coating withstands aggressive chemical exposure.

Acid Handling Pump Protection

Vertical pumps at a refinery suffered chemical attack from sulfuric acid. Belzona 4311 Magma CR coating, designed for aggressive chemical immersion, was applied to protect the volute and impeller—delivering a durable, cost-effective solution.

This pump volute was eroded by abrasive materials suspended in the water flow.

Belzona 2111 elastomeric lining protects pump volute from abrasives.

Wastewater Pump Erosion Elastomeric Repair

A high chrome alloy wastewater pump suffered severe erosion from suspended solids. After grit blasting, Belzona 2111 High Build Elastomer coating was applied to protect against further damage, extending service life and reducing maintenance.

Let’s Restore Your Pumps—Fast!

Don’t wait for part failures or lengthy lead times. Partner with Banks Industrial Group for proven repair solutions that keep your pumps running longer and stronger. We deliver efficient, site-specific pump corrosion repairs with certified technicians focused on safety and fast turnaround. Call 856-687-2227 or email our pump repair experts today for a fast quote.