Belzona Coating For Pumps

Corrosion, erosion, and internal wear can reduce pump efficiency, increase energy costs, and lead to early failure. Banks Industrial Group provides pump coating services using advanced Belzona epoxy systems to restore internal surfaces, reduce hydraulic losses, and extend equipment life. Our cold-applied coatings protect components like impellers, volutes, and vanes—reducing friction, improving flow, and boosting efficiency. No hot work is required, and most applications are completed quickly to avoid disruption. We offer these services directly to municipal and industrial maintenance teams, as well as a subcontracted solution for pump repair contractors seeking reliable coating expertise with fast, safe, and responsive service.

What We Like About Belzona Pump Coatings:

Trusted worldwide for decades, Belzona coatings are supported by extensive testing and real-world success. They are suitable for application to volutes, casings, impellers, diffusers, vanes, cutwaters, pump bowls, and other critical components to enhance efficiency and ensure long-term protection from wear.

-

Improve Efficiency up to 20%: Belzona reduces internal surface roughness, allowing fluid to flow more easily and reducing energy demand – up to 12% for new pumps, older pumps up to 20%

-

Reduce Energy Costs Immediately: Smoother flow paths and reduced friction result in less power required to move the same volume

-

Rapid ROI: Efficiency payback periods generally under one year for continuously running pumps

-

Extend Equipment Life: Coatings create a tough barrier against corrosion, erosion, and chemical attack – protecting vital pump internals for years

-

Avoid Costly Replacements: Metal refurbishment and protective coatings offer a long-term alternative to new pump components, preserving capital budgets

-

No Hot Work Required: Cold-curing application eliminates the risks and delays associated with welding and thermal coatings

-

Fast Turnaround, Minimal Downtime: Most coating applications are completed in days, allowing you to return to full capacity quickly

-

Potable Water: Optional coatings safe for contact with drinking water are available

-

Backed by Belzona’s Proven Performance: Trusted worldwide for decades, Belzona coatings are supported by extensive testing and real-world success

Talk to a Pump Coating Specialist

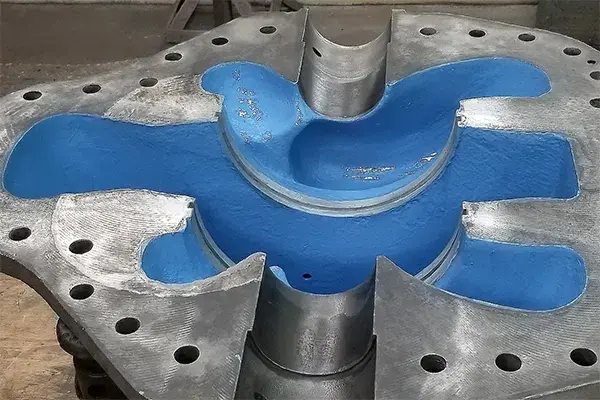

We applied energy saving Belzona 1341 SuperMetalGlide hydrophobic coating as part of the refurbishment of this split case centrifugal pump.

What is a Hydrophobic Coating, and Why Use it?

Belzona 1341 hydrophobic protective coating forms a durable, high-gloss, ceramic epoxy barrier that actively repels liquids from pump surfaces. This ultra-smooth finish significantly reduces friction and turbulence inside the pump, which means less energy is needed to move fluids—improving overall pump efficiency and lowering operational costs. By isolating the metal from corrosive fluids, the coating helps prevent rust, pitting, and erosion, dramatically extending the pump’s service life and maintaining peak performance over the long term.

Both new and existing pumps benefit from this advanced coating solution. Its simple, cost-effective application minimizes downtime and quickly delivers a return on investment through energy savings and reduced maintenance

BIG Pump Coating Examples

Casing with erosion damage is grit blasted to near-white metal.

Areas of metal loss are filled with Belzona 1111 epoxy paste.

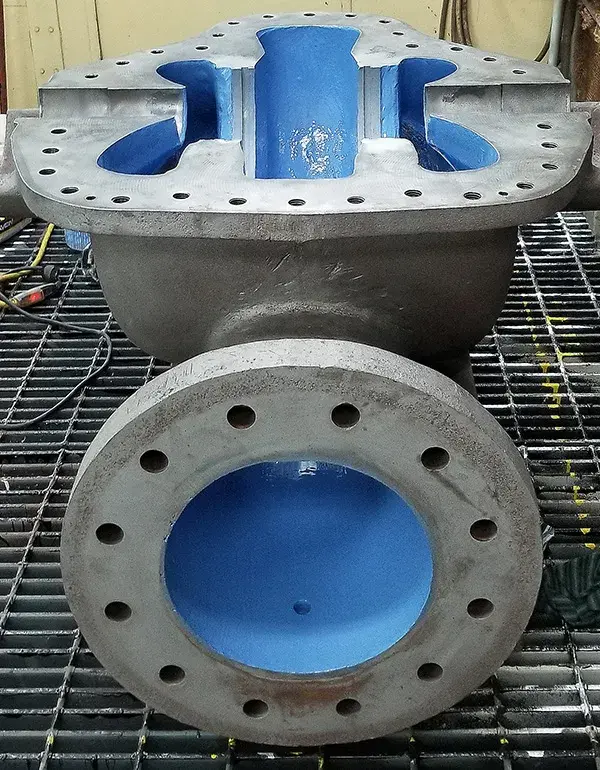

Volute is re-profiled and first coat of gray color Belzona 1341 is applied.

Second coat of blue color Belzona 1341 is applied to all internal water ways.

We Restore Lost Pump Efficiency

This industrial suction pump experienced corrosion and erosion at the surface where the open impeller vane tips operate, resulting in a 38.8% loss of efficiency. The severely corroded volute casing was restored using Belzona 1111 epoxy paste and re-profiled for optimal fit with the impeller vane tips. A protective coating of Belzona 1341 was then applied to enhance hydraulic efficiency, flow rate, and head performance.

Already seeing wear such as this? Please see our pump repair page for more information on refurbishment services.

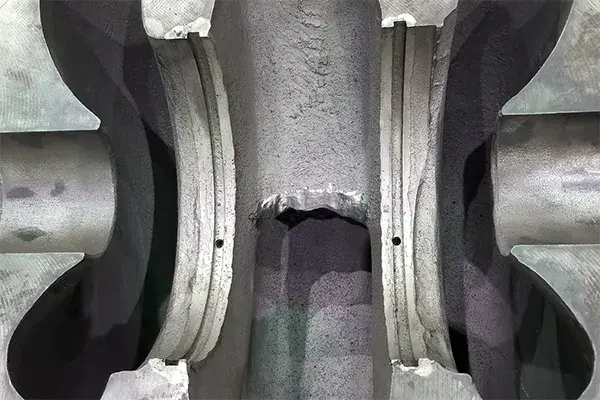

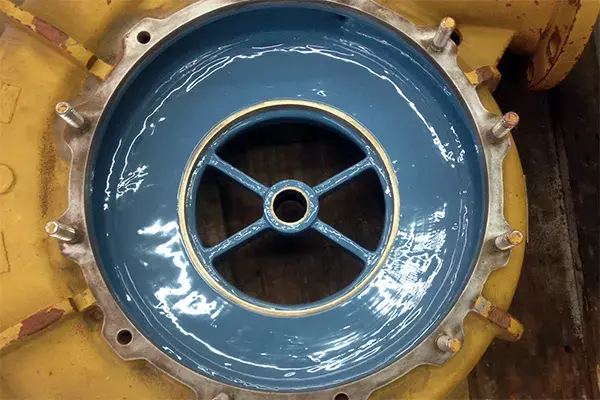

Before: Damaged wear ring seats and volute are grit blasted for repair work.

After: Wear ring seats rebuilt and pump efficiency coating applied.

Centrifugal Pump Volute Coating

Our technicians restored cracked ring seats using Belzona metal repair epoxy and specialized forming techniques. To further enhance performance, the volute was coated with Belzona 1341 hydrophobic coating.

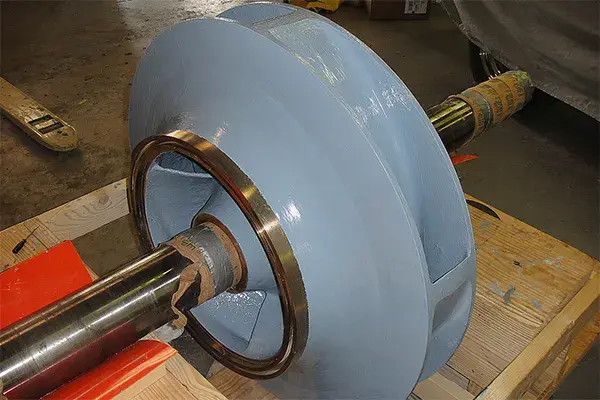

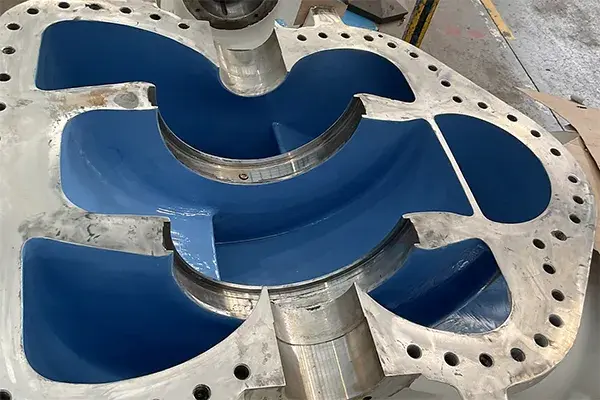

Open impeller coated with Belzona 1341 to enhance efficiency in municipal pump.

Closed impeller coated with Belzona 1341 to increase high-pressure pump efficiency.

Pump Impeller Ceramic Coating

New pump impellers coated with Belzona 1341 to increase energy efficiency and extend service life. Because energy consumption is a pump’s largest lifetime cost, applying an efficiency coating helps reduce expenses and delivers substantial long-term savings.

Metal loss from corrosion and erosion is repaired with Belzona 1111.

Penstock components are coated with Belzona 1341 to improve hydro efficiency.

Penstock Coating

We restored these penstock components in a hydro intake system by rebuilding metal loss and applying Belzona 1341 coating. This process reduces friction, increases efficiency, and protects against future wear.

Before: Rusted fire pump volute leads to pressure loss and reduced pump reliability.

After: Repair and protective coating extend service life and improve reliability.

Fire Pump Coating

Frequent periods of inactivity led to corrosion in multiple seawater fire pumps, requiring replacement every few years. After rebuilding areas of metal loss with Belzona 1111 and applying a Belzona 1341 protective coating, service life has increased by up to three times.

Before: split case pump volute prepped for coating application.

After: Belzona 1341 hydrophobic pump coating applied.

Split Case Pump Efficiency Coating

An aging split case pump at a water treatment plant was refurbished and protected with Belzona 1341 coating to extend service life and improve efficiency. Applying this coating during refurbishment reduces energy costs and delivers significant long-term savings.

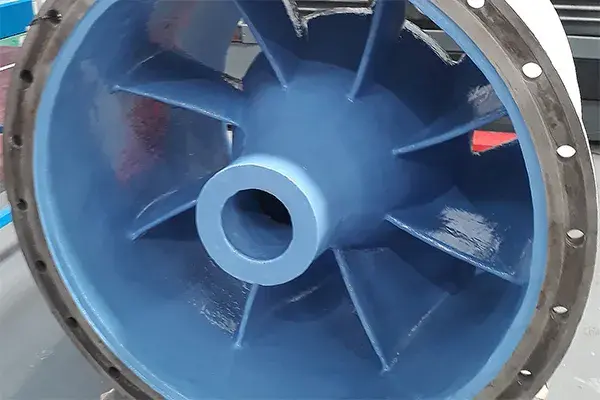

Axial flow water pump diffuser vanes coated with Belzona 1341.

Water pump suction bell coated with Belzona 1341 hydrophobic coating.

Axial Flow Hydrophobic Pump Coating

This axial flow pump at a municipal water plant had significant erosion damage, reducing flow and efficiency. With replacement parts unavailable and a new diffuser costing $50k, Belzona materials were used to repair the damage and enhance efficiency for a much lower cost.

Before: corroded vortex impeller and closed impeller.

After: Impellers and casings are coated with Belzona 1341 to enhance efficiency.

Cooling Water Pump Efficiency Coating

After 15 years service, damage from erosion and corrosion caused efficiency loss in 12 cooling water pumps. Pump parts and housings were grit blasted, then coated with Belzona 1341. Results were 10-12% less power consumption, 12% more pressure and 12% higher head.

Before: New hydro turbine awaiting Belzona pump coating application.

After: Hydro turbine with performance enhancing pump efficiency coating.

Hydro Turbine Efficiency Coating

A new hydro turbine at a municipal power plant was coated with Belzona 1341 to enhance protection and boost operational efficiency, resulting in increased revenue. The investment paid for itself within three months.

Belzona Pump Coatings For Sale

Repair Technology, our sister company, is the authorized Belzona distributor for Delaware, New Jersey, Eastern Pennsylvania, and Western New York. Please visit their website for details on Belzona pump coating product sales.

Ready to Cut Energy Costs and Extend Pump Life?

Banks Industrial Group delivers custom Belzona epoxy pump coating solutions that boost efficiency and protect your assets. Our certified technicians ensure expert application and strict safety, minimizing downtime and restoring your operations fast. Rely on BIG for your pump coating solutions. Call 856-687-2227 or email our protective coating experts today for a fast quote.