Storage Tank Repair Service

Banks Industrial Group delivers fast, safe, and cost-effective aboveground storage tank repair using advanced Belzona® composites. We restore corroded, leaking, or damaged tank shells, roofs, and bottoms without hot work or lengthy shutdowns. Our cold-curing methods rapidly repair thin-wall and through-wall defects, often while tanks remain in service. From corrosion under insulation to weld seam leaks and settlement damage, our turnkey solutions reduce downtime, extend tank life, and improve reliability. Ideal for chemical plants, refineries, terminals, wastewater treatment, and other industrial sites seeking to minimize risk and maintenance costs.

Reliable Repair Contracting for All Types of Storage Tanks

We repair a wide range of tanks, including carbon steel, stainless steel, fiberglass (FRP), chemical, potable water, petrochemical, fire suppression, food storage, wastewater, and process vessels. Our services cover:

-

Metal Loss: Reinforcement and repair of steel tank walls, floors, and roofs weakened by rust, corrosion, erosion and chemical attack

-

Leak Sealing: Leaks from cracks, holes and deteriorated protective linings requiring urgent repair

-

API 653: Aboveground storage tank maintenance and alteration for compliance with API 653 standards

-

Fiberglass Reinforced Plastic (FRP): tank repair of cracks and delamination

-

Concrete Tanks: damaged by settlement cracks, spalling and failed linings

Why Choose Banks Industrial Group?

-

Tailored, Problem-Solving Approach: BIG collaborates with clients to deliver practical, cost-effective repair solutions—never overselling or applying unnecessary fixes

-

Proven Belzona Expertise: We use high-performance Belzona materials to deliver repairs that are as strong as (or stronger than) metal, extending equipment life, and protecting your investment

-

Speed Without Compromise: Our cold-applied, fast-curing techniques minimize downtime, with most repairs completed in just days—not weeks—keeping your plant running

-

Versatile Repairs for Complex Needs: From wet, oily surfaces to irregular shapes, BIG brings the right materials and in-house expertise to tackle the toughest repair challenges

-

Safety You Can Trust: With 100% of our team OSHA 30 certified and top-tier ISNetworld safety ratings, BIG ensures every job is done safely and responsibly

Need Tank Repair Service?

Request an estimate or consultation.

The Difficulty of Storage Tank Corrosion Repair

Corrosion in storage tanks leads to leaks, safety hazards, environmental damage, and productivity loss. It often occurs in hard-to-inspect areas and worsens over time if undetected. Traditional welded repair methods are slow and risky, especially in flammable environments, requiring full tank shutdowns to safely empty, clean, then fix the damage. In some cases, welded repairs are not feasible due to operational challenges such as complex shapes, part availability, or damage severity.

Belzona Repair Compounds Offer a Safe Alternative

Banks Industrial Group uses Belzona composite tank repair methods as a safe, efficient alternative to welding. These room-temperature curing compounds match welded strength without hot work, allowing most tank repairs to be completed in one to two days—often while the tank remains in service. Our durable solutions minimize downtime and extend tank life without the time and cost of traditional maintenance. Contact us today for an estimate.

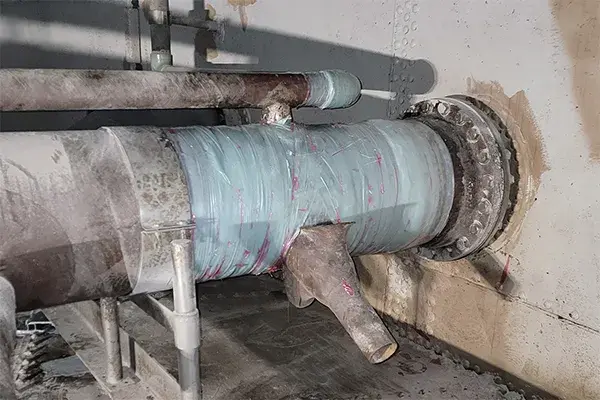

Complex tank shapes are easily repaired using composite wrap techniques.

We used specialized epoxy metal paste and carbon fiber wrap to fix holes in this process vessel at a New Jersey petrochemical plant.

What to Expect From BIG

Our crews proceed quickly and safely. We complete most repairs in one or two days; some require only a few hours. In many cases, systems remain online without need for draining and clean-out, saving you time, money and labor.

- Assess the damage and match a solution appropriate to your operating environment and expectations

- Clean and prep the surface, which could include grinding and abrasive blasting to remove failed coatings, rust and debris

- If needed, we repair areas of metal loss, pitting and holes with a suitable Belzona Super Metal epoxy paste

- Apply composite wrap and/or cold bond plates that are fit for purpose to repair damage and restore structural integrity

- After curing, we apply protective coatings when needed to shield against UV, heat, moisture and/or corrosive chemical exposure

- If required, reapply insulation to tanks or vessels

BIG Industrial Tank Repair Examples

Before: holes in the tank shell halted the operation of a stainless steel storage tank.

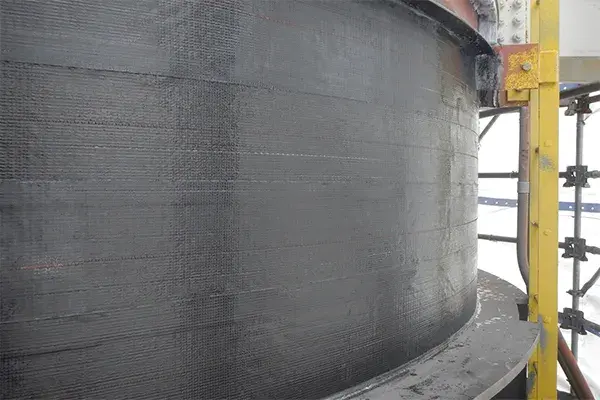

After: Composite wrap strengthens tank shell for fast repair and lasting service.

Bulk Storage Tank Hole Repair

BIG provides expert tank restoration services for industries like chemical processing, energy storage, food and beverage, petrochemical, and wastewater. We use top-quality Belzona materials for fast and lasting repairs.

Before: metal loss risked this chemical processing vessel's reliable operation.

After: Metal loss rebuilt and strengthened using a carbon fiber composite wrap.

Repair of Process Vessel Corrosion

BIG repairs tanks and vessels suffering from thin-wall conditions using specialized Belzona composite tank wrap. Repairs are done fast, on-site to minimize downtime – often while equipment remains in operation. They are durable and long-lasting to extending the service life of industrial equipment.

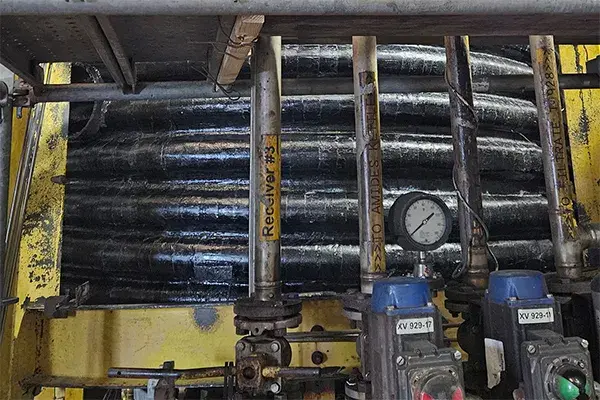

Composite wrap repair strengthens the domed bottom of this air separator tank.

Carbon fiber composite was used to reinforce the process vessel's shell walls.

Repair of Tanks & Vessels With Complex Geometries

BIG's composite tank repair techniques efficiently fix complex-shaped tanks and vessels on-site, using high-quality materials to reduce downtime and extend service life.

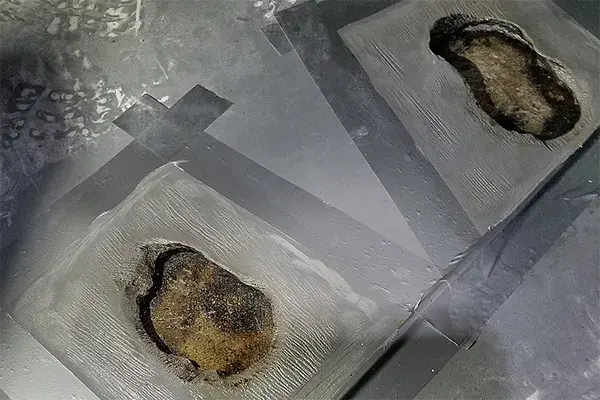

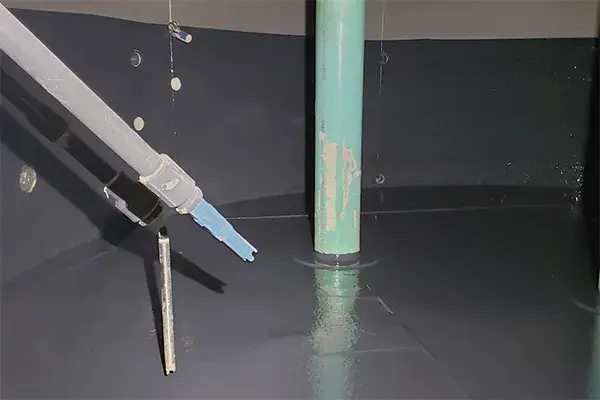

Before: Holes in a wastewater scrubber tank bottom prepped for repair.

After: Holes repaired with Belzona metal rebuild and sealed with protective coating.

Scrubber Tank Floor Hole Repair

BIG offers fast scrubber tank repair services. We use cold-cure tank repair materials to fix damage and quickly get your equipment back in action. These materials resist erosion, corrosion, abrasion, and chemical attacks, extending the life of your scrubber assets. Discover more about internal tank coating.

This tank cone roof is corroded, causing holes and containment loss.

Patch repairs are carried out using Belzona composite repair materials.

Bulk Storage Tank Roof Corrosion Repair

BIG expertly repairs holes and corrosion on metal tanks, silos, and vessel roofs. Utilizing advanced cold-cure Belzona composite materials, we ensure rapid service and enhanced durability, providing a reliable solution for maintaining structural integrity and extending the lifespan of industrial assets.

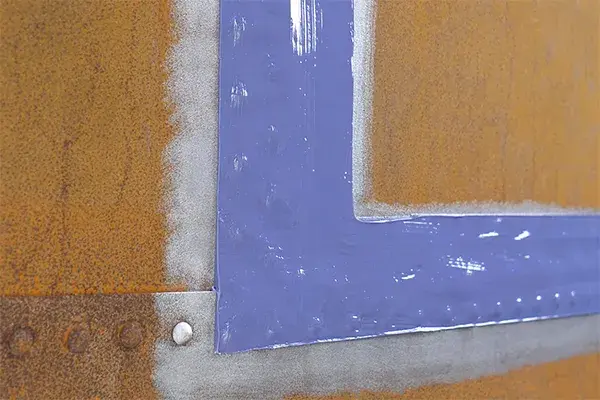

Before: Fluid leaks from the riveted seam of a metal storage tank.

After: Leak sealed and repaired with specialized Belzona paste grade materials.

Riveted Tank Seam Leak Repair

We fix leaks in storage tanks caused by loose or corroded seams in riveted metal plates by using specialized Belzona epoxy tank repair materials. Our cold-curing repairs quickly get your tank back in service.

Before: This insulated fiberglass tank is currently out of service because of cracks.

After: Cracks sealed using Belzona paste and reinforced with a composite wrap.

Fiberglass Tank Shell Repair

We use the same effective epoxy and composite repair methods for fiberglass tanks as we do for metal ones. By sealing the cracked end with Belzona paste and reinforcing it with fiberglass and carbon fiber wraps, we ensure a quick return to service at a fraction of the replacement cost.

Before: Damaged support brackets and eroded fiberglass tank shell.

After: Erosion repaired and replacement brackets cold bonded to tank shell.

Internal Fiberglass Tank Repair

We used Belzona materials to quickly restore eroded and cracked areas in this fiberglass tank. Custom support brackets were made and securely attached to the tank shell using cold bond epoxy. This allowed us to swiftly return the tank to service, prolonging its lifespan and reducing costs for the plant.

This manifold repair in an energy storage tank was done without hot work.

Cold-bond re-attachment of dislodged distribution manifold support.

Aboveground Storage Tank Interior Repairs

BIG's cold-cure repairs efficiently fix internal tank parts, minimizing downtime and ensuring smooth operations. This reliable, cost-effective method extends tank system life.

We fixed this leaking valve nozzle insert on-site using a specialized epoxy paste.

We fixed this pipe insert tank leak using epoxy paste and a carbon fiber patch.

Tank Nozzle Insert Repairs

BIG repairs tank inserts, nozzles, flanges, and fixtures that often suffer from corrosion and leaks. We use specialized Belzona materials to effectively seal leaks and fix damaged areas. Many repairs can be completed while systems remain operational.

Before: Water behind tank insulation leads to hidden corrosion at the base.

After: Corrosion removed, tank chime sealed, and protective coating applied.

Tank Chime Corrosion Repair

We offer corrosion under insulation repair and a method to prevent moisture buildup at the tank base by raising insulation to expose the chime angle, allowing water to drain and simplifying API 653 tank maintenance inspections. We also provide tank chime sealing service.

Learn How To Improve API 653 Aboveground Storage Tank Inspection

Download our API 653 whitepaper to cut inspection costs and prevent failures. You may also explore these five expert blog posts on API 653 tank maintenance best practices:

Chemical Hopper Repair Customer Success Story

Deteriorating chemical hoppers threatened safety and uptime—see how BIG’s cold-applied composite repair kept this NJ plant running smoothly without shutdown or hot work.

BIG Provides Rapid Aboveground Storage Tank & Process Vessel Repair Service

We design storage tank repair solutions that fit the site requirements and operating conditions of our clients. Our field technicians are validated composite repair personnel who bring a strong work ethic and commitment to safety to each project. We work efficiently – minimizing downtime, and getting your operation running again as fast as possible. Trust BIG to cover your tank repair needs! Call 856-687-2227 or email our storage tank repair experts today for a fast quote.