Concrete Tank Repair Service

Fast, Durable Solutions To Extend Asset Service Life

Banks Industrial Group is a concrete tank repair contractor that provides specialized service for wastewater treatment, chemical and other industrial applications. We quickly restore deteriorated concrete and apply protective coatings to extend the service life of clarifiers, settlement tanks, water tanks, lift stations, vaults and other concrete structures that must withstand extreme operating conditions. You can rely on our rapid solutions to minimize downtime and place your valuable assets back in service for the longterm.

Why use our service?

-

Avoid costly demo and reconstruction by restoring damaged concrete

-

We use premium materials with a proven record of success for wastewater and industrial applications

-

Fast curing materials allow for rapid work and shorter asset downtime

-

Most repairs are completed and ready for service in hours or days – not weeks

-

Protect tanks operating under continuous immersion, chemical attack and abrasive conditions

-

NSF ANSI 61 approved coatings suitable for potable water contact available

-

No hot work needed – materials are cold applied and rapid curing at room temperature

-

VOC and solvent-free materials lower health and safety risks in confined spaces

-

BIG is fully insured, OSHA compliant and ISNetworld Certified A+ with documented safety conformance

Need Concrete Tank Repair?

Request an estimate or consultation.

Concrete Problems With Concrete Tanks

Concrete tanks are durable structures well suited for storing and processing water. However, problems can occur as they age. Time and exposure to harsh operating conditions eventually cause deterioration leaving these structures vulnerable to increased wear, corrosion, potential leaks and loss of containment.

Concrete tank problems typically result from:

- Cracks due to tank settlement that allow water penetration and leaks

- Freeze thaw cycling causes cracks and separated joints to leak

- Wet dry cycling causes cracks and separated joints to leak

- Chemical attack wearing away coatings and linings and exposing concrete to damage and corrosion

- Abrasion wearing away coatings and linings and exposing concrete substrate to damage

- Erosion damage to concrete surfaces

- Spalled concrete and structural damage from rebar corrosion

Most concrete tank problems are manageable if action is taken promptly. However, deterioration and repair costs will significantly increase if maintenance is ignored. Eventually, the tank will fail and complete replacement will be required to fix the problem.

BIG provides a range of repair and coating services to prolong the service life of these valuable assets. Our skilled field crews work in a safe and efficient manner to minimize downtime and quickly place your tank back in service.

Our concrete tank services include:

- Remove areas of deteriorated concrete, repair and resurface with specialized epoxy mortar

- Repairing cracks using hydrophilic & hydrophobic chemical grout for wet leaks & epoxy resin injection for structural dry concrete cracks

- Replacing failed expansion joint seals with specialized elastomeric to prevent leaks

- Application of specialized protective coatings to shield concrete from erosion, corrosion, abrasion and chemical attack

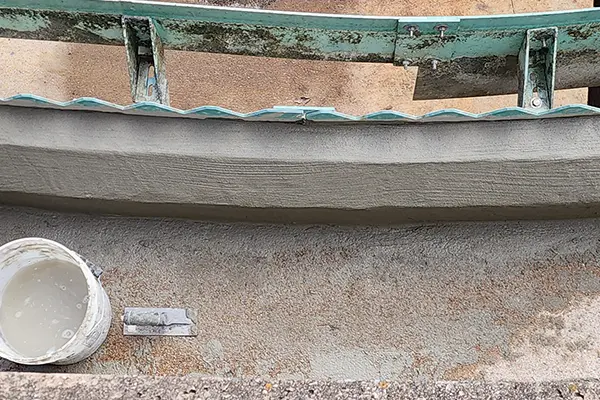

Clarifier tank wall repaired with epoxy mortar.

Protective coating in chlorine contactor tank.

Concrete Tank Problems We Solve Include:

Spalled tank walls in need of repair.

Concrete repaired with epoxy mortar.

Deteriorated Concrete Tank Walls and Floors

We remove areas of spalled, deteriorated concrete then patch with non-porous Belzona materials that bond tenaciously and are proven to withstand extreme conditions. Specific formulations are selected to match your site conditions and will hold up to constant immersion, chemical attack, abrasion and impact.

Failed coating and damaged concrete.

Concrete wastewater tank restoration.

Failed Concrete Coatings and Linings

BIG will remove run-down coatings and linings, repair any concrete defects, then apply a fresh protective coating. Our premium coatings such as Belzona 5811 have a proven record of erosion, corrosion and chemical protection for equipment operating under immersion.

Clarifier trough erosion repair.

Clarifier protective coating application.

Eroded Clarifier Troughs

Concrete clarifier troughs are vulnerable to erosion and chemical attack from constant water flow. BIG restores eroded trough concrete to its original profile and can apply a protective coating to further extend service life.

Cracked expansion joint on clarifier wall.

Rebuilt joint with elastomeric seal.

Crumbling Clarifier Skimmer Wheel Track

Clarifier wall tops deteriorate from skimmer arm movement and freeze thaw which causes cracks and separated expansion joints. This hurts smooth skimmer operation when wheels bump and impact the joints. BIG quickly rebuilds concrete to original profiles and seals joints with elastomeric.

Tank with damaged expansion joints.

Joints sealed with Belzona elastomeric.

Separated Expansion Joint Seams

We use high performance elastomeric such as Belzona 2211 to replace worn expansion joint and abutment seals. 2211 will withstand up to 700% elongation and exposure to a variety of chemicals. When necessary we will also repair cracked concrete edges and nosings with high performance epoxy mortars to ensure a reliable seal.

Grout injection used to stop water leak.

Epoxy resin used to bond structural crack.

Concrete Tank Leaks

We use epoxy or polyurethane grout injection repair methods to repair cracks and leaks caused by concrete shrinkage, settlement and freeze thaw movement. Epoxy grout restores structural integrity. Polyurethane grout will stop leaks.

Underground Water Storage Tank Coating Customer Success Story

See how Banks Industrial Group restored a deteriorated coastal water tank with NSF-certified coatings—saving time, cost, and compliance headaches in a sensitive National Park location.

Read Underground Water Storage Tank Coating Customer Success Story.

Banks Industrial Group is Your Source for Concrete Tank Repair Service

Banks Industrial provides concrete tank repair and protective coating services for water, wastewater and industrial applications. We understand the high cost of downtime and work diligently to apply an effective, long-lasting repair with a fast return to service. For more information please call 856-687-2227 or email our concrete tank repair experts today for a fast quote.