ErectaStep Industrial Work Platform Installation Case Study

Installing ErectaStep industrial work platforms to improve facility layout and enhance operational efficiency

Building Specs:

E-Commerce Fulfillment Center

Pain Point:

Inefficient Facility Layout Caused by Telescoping Conveyor Belts

Fulfillment Center’s Vision:

“To exceed customer expectations with the fastest delivery possible.”

Fulfillment Center’s Challenge:

The fulfillment center uses telescoping conveyor belts to service multiple truck loading docks. When extended, the conveyor belts limited foot traffic, complicated servicing processes, and disrupted communication between supervisors and staff.

The Challenge’s Impact on Day-to-Day Work:

The conveyor’s large setup required workers to walk far distances to find safe access paths, perform daily functions, and complete simple out-of-reach tasks. These obstacles significantly hindered loading staff efficiency, particularly during the center’s busiest time of year—the holiday season.

During the holiday season, the center seeks to process a million packages per day. The chronic inefficiencies caused by the conveyor setup routinely threatened the center’s ability to meet its daily goals. A solution was needed for the fulfillment center to fulfill its contractual obligations.

For more information about our industrial work platforms, and other industrial solutions, contact our team today by calling 856-687-2227.

Banks Industrial Group Fulfillment Center Solution: ErectaStep Industrial Work Platforms

Banks Industrial Group (BIG) eliminated the fulfillment center’s efficiency problem by installing ErectaStep industrial work platforms around the conveyor belt setup. With the aid of three ErectaStep stair and platform sets, BIG enhanced the fulfillment center by:

- Installing a solution that allowed staff to transit easily up, over, and around obstacles

- Creating a safer environment for loading packages

- Performing the ErectaStep installation without impacting the center’s daily operations

The client sought a solution for their conveyor belt challenge just before the start of the holiday season. Given the rapidly-approaching spike in demand, the client needed a quick fix that wouldn’t impact worker productivity during installation.

This client valued speed. To meet the client’s needs, the BIG team:

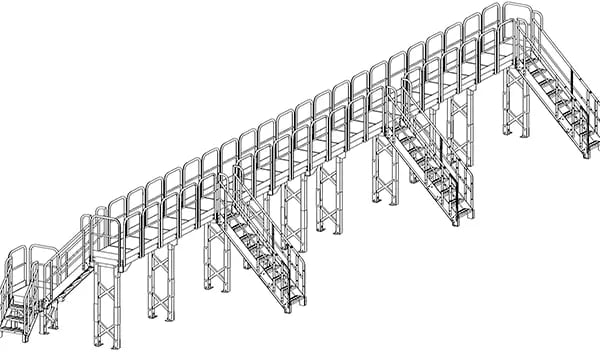

- Quickly established the project’s scope and design requirements: By examining hand drawings from the fulfillment center’s engineers, BIG created three industrial work platforms, with each structure consisting of just under 100 modular parts and spanning 70 feet apiece. The client engineers received drawings of each platform just days after the initial scope definition.

- Processed, fabricated, and delivered the order in less than a week: After the purchase order was submitted, the BIG team took less than a week to deliver the fulfillment center’s platforms. While loading the platform parts, the team took extra precautions to minimize their impact on the fulfillment center’s operations. All platform parts were packaged and loaded to allow for quick unloading and minimal use of floor space.

- Installed the industrial work platforms in five days: To accommodate the fulfillment center’s tight schedule, BIG sent extra labor to the job site. At the center, the BIG team completed the installation in just five days. While onsite, the BIG team also reconfigured the design to better fit the client’s needs:

- The first adjustment accounted for an error in the hand drawings that were used to guide the ErectaStep platform design

- The second adjustment satisfied additional access needs

- The first adjustment accounted for an error in the hand drawings that were used to guide the ErectaStep platform design

Actual design configuration drawing used to layout the conveyor crossover bridge.

Key Takeaways

During installation, BIG’s efficiency and ability to address onsite complications enabled the team to meet the center’s compressed time schedule. Although the original proposal required three weeks of installation time plus one week delivery, the BIG team packaged, delivered and installed in under two weeks, including two system reconfigurations. To meet the client’s needs, BIG:

- Finished the entire project 15 business days from the purchase order receipt date

- Completed installation within just five days

- Accomplished two onsite system reconfigurations without a single delay

- Provided the center’s operation’s staff with sets of OSHA-compliant stairs for a safer, more efficient work area

BIG’s ErectaStep system provided the fulfillment center with a quick solution to their conveyor setup problem. The ErectaStep industrial work platforms created safe, convenient pathways for workers to move around the facility, enabling quicker foot travel, easier access to the center’s loading docks, better worker communication, and faster problem response times.

See the Full Erectastep Catalog:

Banks Industrial Group specializes in above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative, and cost-saving solutions help keep your facility running efficiently. For more information about our industrial work platforms, and other industrial solutions, contact our team today by calling 856-687-2227.