Flange Face Repair Services

Flange faces are susceptible to corrosion and erosion due to harsh environmental conditions, chemical reactions, and general wear and tear. If ignored, corrosion and erosion can lead to harmful leaks, product loss, downtime, and various workplace safety hazards.

To keep operations safe and efficient, Banks Industrial Group (BIG) offers quick and long-lasting flange face repair services. Our Belzona flange face repair kits are applied in-situ to help your operation:

-

Reduce downtime

-

Avoid hot work

-

Reduce or eliminate spare flange inventory

We also provide repair kits and training for your staff to perform repairs.

Need Flange Face Repair?

Request an estimate or consultation.

| BIG Flange Face Repair Services Benefits | |

| Fast Results | Our services quickly restore damaged flange faces |

| In-Situ Application | Belzona flange face forming materials can be applied in-situ for minimal downtime |

| Corrosion Resistance | Our Belzona kits adds corrosion resistance to old and new flange faces |

| Chemical Resistance | Belzona resists a wide range of chemicals |

| Proactive Protection | BIG’s flange forming technology isolates dissimilar metals to prevent galvanic corrosion |

| Pedestrian Protection | Stop vehicles while allowing pedestrian access |

| No Hot Work | Belzona applies and cures at room temperature—no hot work required |

| No Safety Risks | BIG’s solvent-free products reduce health and safety risks |

| Multiple Sizes | Our kits accommodate most common pipe schedules in 2-in, 3-in, and 4-in sizes |

| Highly Portable | You can easily transport lightweight repair kits to emergency situations |

| Reusable | Belzona flange face formers can be reused hundreds of times, eliminating the need for a large replacement flange inventory |

Damaged Flange Faces Can Lead to Leaks, Shutdown, Lost Productivity, and Environmental Contamination

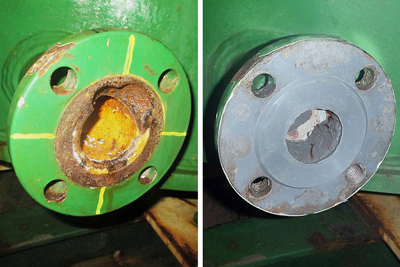

Corrosion and erosion damage hidden between pipe flange faces will weaken the gasket seal and increase your risk of pipe failure. In many cases, the flange face conceals the deterioration as well. Without early detection, the deterioration often remains undiscovered until a leak occurs. As a result, companies often face:

-

Expensive periods of downtime

-

Product loss

-

Environmental cleanup

-

Potential worker safety hazards

To make matters worse, conventional flange repair methods typically require time-consuming shutdown periods for hazardous cut and weld replacements.

Before and after repair of severely damaged pipe flange face.

Each flange face former in the repair kit can be reused hundreds of times.

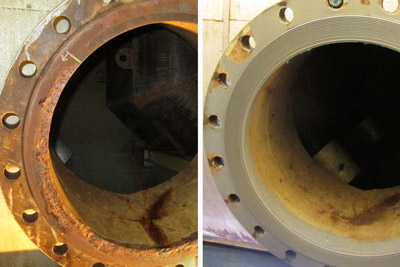

BIG performs specialized metal repair of large manway flange faces.

Flange face rebuilding demo video.

Flange Face Repair Services by Banks Industrial Group

Banks Industrial Group provides quick and cost-effective flange face repair services. Using Belzona flange face-forming materials, we can restore damaged faces in situ without hot work or machining.

Belzona’s rapid application and cold-curing capability reduce operational downtime and disruption. Additionally, you can use our flange-forming technology to isolate dissimilar metals and prevent galvanic corrosion proactively.

To prevent crevice corrosion, check out our protective flange encapsulation system.

Banks Industrial Group specializes in above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative, and cost-saving solutions help keep your facility running efficiently. For more information about our flange face repair services, contact our team today by calling 856-687-2227.