Customer Success Story: Underground Water Tank Restoration & Coating

Location: Sandy Hook/Fort Hancock, NJ underground water storage tank.

Pain Point:

Deteriorated concrete and corroded piping threatened the safety and integrity of a coastal underground water storage tank.

The Challenge:

The customer needed a reliable, NSF-approved repair to restore a deteriorated potable water tank in a confined coastal location.

The Challenge’s Impact On Day-to-Day Operation:

The tank’s degraded concrete and corroded piping compromised its ability to safely store potable water, posing risks to system reliability and public health. Continued deterioration could have led to leaks, contamination, or costly replacement. The remote, underground location within a protected coastal park added logistical challenges, requiring a fast, compliant solution that minimized disruption to ongoing rehabilitation work at the site.

BIG Solution: Durable, NSF-Certified Tank Lining Restores Integrity in Coastal Environment

A construction firm specializing in environmental remediation was contracted to restore a deteriorated underground water storage tank at Sandy Hook’s Fort Hancock in a New Jersey National Park. The tank, crucial for potable water storage, had suffered years of concrete degradation and severe pipe corrosion due to its coastal location.

Having partnered successfully in the past, the contractor once again turned to Banks Industrial Group (BIG) for their trusted expertise in protective coatings and concrete repair.

BIG’s team mobilized quickly, setting up confined space access, scaffolding, lighting, and dehumidification systems. The tank’s interior—roughly 10,000 square feet—was pressure washed and mechanically prepared to achieve the required surface profile. Technicians rebuilt spalled concrete and sealed hairline cracks with NSF-approved materials. Corroded utility piping was reinforced with Belzona 1111 Supermetal paste and coated with Belzona 5812DW epoxy for long-term corrosion resistance.

To complete the relining, BIG applied Belzona 5812DW—a 100% solids, NSF/ANSI 61-approved epoxy—at a minimum 16 mils DFT across all internal surfaces, ensuring durable protection for potable water immersion. The project wrapped in just three weeks.

The BIG Advantage:

BIG’s turnkey solution eliminated the need for costly replacement, minimized downtime, and ensured the tank met modern potable water standards. The client praised the crew’s professionalism and noted: “I'll definitely be giving Banks a call when our next tank project comes around.”.

Why Belzona 5812DW was the right choice:

- Certified safe for drinking water

- Exceptional corrosion resistance

- Cold-applied—no hot work required

- Adheres to steel, concrete, and mixed substrates

- Speeds project timelines with fast curing

BIG’s performance once again proved that safety, quality, and trusted relationships deliver lasting results.

Surface prep of 10,000 sq. ft. underground water storage tank.

Underground Water Tank Restoration & Epoxy Coating Application Details

Pressure washing and patching areas of deterioration restore the concrete to correct profile.

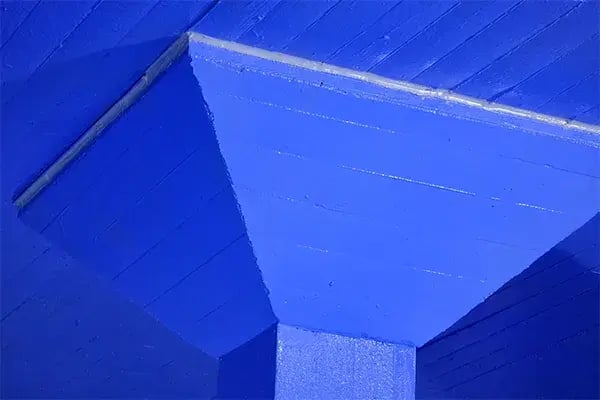

First coat of gray Belzona 5812DW suitable for contact with drinking water is applied to tank walls.

The second layer of blue Belzona 5812DW achieves the required protective thickness.

Detail of corroded pipe shown within the underground water storage tank.

Corrosion was removed and damaged areas were repaired with Belzona 1111 metal repair paste.

After restoration, internal pipes also received a Belzona 5812DW protective coating.

Concrete joint seams were sealed with NSF-compliant elastomeric material.

Elastomeric concrete joint seam seal at the top of an internal support column.

The tank entryway was coated with Belzona 5812DW and fitted with a new ladder, replacing the old wall rungs.

Looking to extend the life of critical infrastructure?

Banks Industrial Group is a trusted provider of concrete tank lining systems for municipal and industrial environments. Please contact us today via email or call 856-687-2227 to learn how our repairs and coatings can extend asset service life, and improve protection, compliance and uptime at your facility.