The cost to repair plant equipment comes in many forms. Lost operations can dwarf the costs of labor and materials, depending on the importance of the equipment to be repaired. Full replacement of equipment rarely fits neatly into a company’s current year capital expense budget. However, plant managers cannot typically afford to wait until the next year’s budget cycle to restore full capability.

Belzona products can save companies time and money with weld-free applications and application (situation dependent) while keeping the equipment online.

Here are five great examples of Belzona repairs that saved money for the customer:

Eroded housing.

Final repair of kort assemblies.

The lower half of the port and starboard Kort nozzle (a ducted propeller fitted with a non-rotating nozzle) drive assemblies on a tug boat suffered from severe erosion on the propeller side of the housing. Welding each eroded housing would have cost the company over $100,000 per assembly. Instead, they chose Belzona 1311 (an epoxy-based repair composite designed for metal repair and protection against the effects of erosion and corrosion) for application to the housing, restoring the nozzle drive assemblies. By using this Belzona product, the owner widened the diameter of the housing, making it more hydrodynamic in the process.

Untreated heat exchanger.

Exchanger after application of 4311.

Hot hydrochloric acid attacked the steel spirals of a heat exchanger for a pigment manufacturer, limiting the life of the exchangers to only a few weeks from failure after discovery of the problem. This company chose Belzona 4311 Magma CR1, a durable epoxy coating for the long term protection of concrete and metal surfaces from chemical attack (especially acids and alkalis). Replacement of the unit required twelve months at a cost of $300,000. Instead, the 4311 solution solved the problem on-site with an initial cure from 6-16 hours and full chemical resistance cure ranging from 5-14 days, depending on the ambient temperature, all at a cost in the hundreds, vice hundreds of thousands, of dollars.

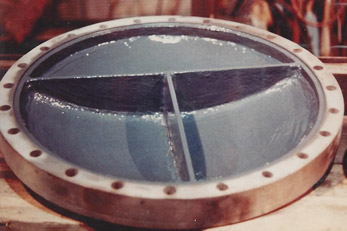

Close up of damaged cover plates.

Repaired cover plates saved hundreds of thousands.

A plant in Alaska replaced ten heat exchangers in the previous year. The stainless steel covers for these exchangers were welded with a carbon steel rod, setting up electrolysis. Replacing these exchangers would cost over $500,000 plus three months of downtime at ~$70,000 per day. To fix the problem, Belzona technicians applied Belzona 1311 (designed to rebuild eroded/corroded materials) and 1321 (a ceramic filled epoxy coating designed to provide erosion/corrosion resistance to metal surfaces) to rebuild the exchangers in seven days, for less than $20,000. Upon inspection one year later, all ten heat exchangers were found in perfect condition.

Corroded tank top to bottom.

Patched steel at bottom of tank saved millions.

The water holding tank in a plastics plant experienced severe corrosion after twenty years of service. Technicians applied steel patches onto the rusted areas of the tank using a layer of Belzona 1121. Failure of this particular vessel would have caused shutdown of the entire unit at a cost of $5,000,000 per week in sales – not a good day for that plant. Fortunately, Belzona repairs took one day at a cost of about $10,000, with the tank in operation during the entire repair.

This pipe was heavily pitted and corroded.

A chemical resistant wrap applied to piping.

The flare line at a petrochemical refinery suffered from severe external corrosion that reduced the thickness of the wall. Technicians used Belzona 1221 (a fast curing composite material for metal repair based on a silicone steel reinforced polymer system – perfect for emergency repairs) to bond a plate to the wall to stop any leaks, then created a temporary wrap of the same material around the area. Next, they wrapped the pipe to rebuild and profile it using Belzona 4301 Magma CR1 High Build (a more durable repair composite for long term metal and concrete protection from a broad range of chemicals, acids and alkalis). Finally, they applied Belzona 1161 (a composite repair coating specifically designed for application to wet and oil contaminated surfaces and underwater applications) on top and encapsulated the adjacent flange.

Despite three days needed for the repair, no shutdown was required, saving this plant at least $6,000,000 in shutdown losses.

Interested in learning more about how a Belzona solution can save your facility money? Schedule a lunch and learn with our team today, and we’ll sustain you and your team with lunch and plenty of information on how to meet your maintenance and repair needs. Email us or call (856) 336-2684 for assistance.