Proven Results in Secondary Containment Area Restoration

Concrete eaten away by acid drips is backfilled with Belzona epoxy mortar.

Final layer of chemical-resistant Belzona 5811 protective coating.

Acid Blending Tank Farm Bund Rehab

We cleaned and prepared all concrete surfaces then backfilled areas of deterioration with Belzona 4131 Magma-Screed epoxy mortar. Next, we applied chemical-resistant Belzona 5811 Immersion Grade protective coating. Work was completed in one week at this New Jersey tank blending farm.

Caustic storage tank containment bund restored and coated with Belzona.

Pump foundations and containment curb coated with Belzona.

Caustic Soda Containment Bund Restoration

We refurbished this secondary containment area for sodium hydroxide storage tanks at a Delaware chemical plant. Areas of concrete deterioration were patched and a Belzona protective coating was applied to extend service life. Non-slip aggregate was added for worker safety.

First layer of Belzona 5811 with non-slip aggregate is applied.

Final layer of Belzona 5811 suitable for constant immersion.

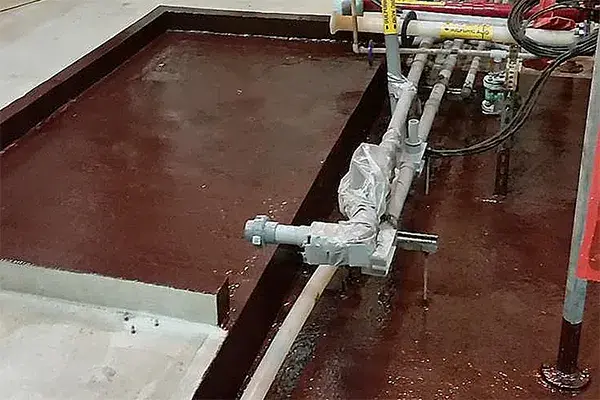

Polymer Defoamer Skid Containment Coating

We restored this secondary containment area at a NJ power plant. The area provides splash and spill protection for a polymer defoamer skid used for industrial water treatment. Non-slip aggregate was added to the Belzona 5811 protective coating to enhance worker safety.

Areas of deterioration backfilled with Belzona 4181 Magma-Quartz.

Final coat of specialized acid-resistant Belzona 4311 Magma CR1.

Sulfuric Acid Secondary Containment Restoration

Acid leaks damaged this secondary containment area. We removed the previous failed coating and backfilled holes with Belzona 4181 Magma-Quartz. Then we applied Belzona 4311 coating to withstand exposure to the strong acid. Work completed within 24 hours during a planned shutdown.

Failed acid tile is removed prior to resurfacing and protective lining.

Belzona 4181 Magma-Quartz provides exceptional acid and heat resistance.

Manufacturing Plant Containment Area Restoration

We restored this worn containment area by removing damaged acid brick, resurfacing and leveling areas of concrete loss, then applying specialized Belzona 4181 Magma-Quartz lining capable of resisting concentrated acid exposure. Work completed in 4 days. See our acid brick repair service here.

Cracked and worn concrete drum pad at a Philadelphia chemical plant.

Containment effectiveness restored with chemical-resistant Belzona.

Hazardous Waste Drum Pad Restoration

We patched areas of concrete deterioration and applied a chemical resistant coating suitable for outdoor UV exposure to restore this drum pad at a Philadelphia chemical manufacturing plant. Cracks were sealed with Belzona 2211 Elastomeric to accommodate weather related expansion movements.

Impending loss of containment in railroad chemical transfer area.

Damaged seams are repaired and Belzona 4311 coating applied.

Railroad Chemical Transfer Area Restoration

We repaired broken seams and applied specialized Belzona 4311 Magma CR1 protective coating to this sulfuric acid splash pad and drain for collecting chemical spills. Work completed in two days.

Prep work to remove deteriorated fiberglass lining in HCI loading area.

Chemical transfer loading area repaired and protected with Belzona 4154.

Chemical Transfer Truck Loading Area Restoration

We removed the failed fiberglass lining, resurfaced areas of concrete deterioration and applied a specialized Belzona 4154 epoxy to withstand hydrochloric acid splashes and truck traffic in this chemical transfer loading area. Garnet aggregate was added for anti-slip to improve worker safety.

Leaking seam seals on a caustic containment bund in a wastewater plant.

Damaged seam seals were removed and replaced with Belzona 2211 Elastomeric.

Secondary Containment Area Seam Sealing

We removed and replaced failed concrete seam seals on this caustic sodium hydroxide secondary containment area. Belzona 2211 Elastomeric was utilized for its chemical resistance, tenacious bond and elongation properties.

Ready to Protect Your Secondary Containment?

Don’t wait for minor deterioration to become a major problem. BIG’s secondary containment repair and coating services can restore your structures, extend their service life, and shield your facility from costly chemical damage. Request a Containment Assessment today, or let us match the right Belzona specification to your chemical environment. For more information please call 856-687-2227 or email our secondary containment coating experts today for a fast quote.