Chiller Coating Service

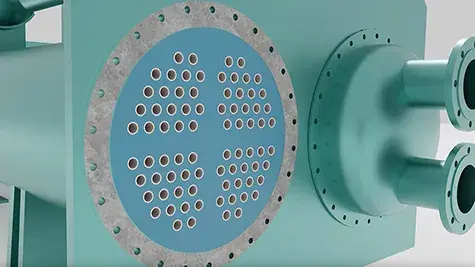

Banks Industrial Group offers expert chiller coating and metal restoration services to repair tube sheets, water boxes, division bars, end caps, and other parts of water-cooled chillers and heat exchangers. We use top-quality Belzona chiller coatings and metal rebuild epoxies known for their reliability. Work is done on-site without hot work by using safe, cold-curing, VOC free materials. Downtime is minimal – coatings cure within hours for a fast return to service. Whether comfort cooling or process cooling, mechanical contractors and facility managers trust us for quick, dependable repairs and protective coatings that extend the life of chillers. Contact us today for a consultation and estimate.

What We Like About Belzona Chiller Coatings

-

Minimize Downtime: Fast, cold-applied repairs reduce disruption to HVAC systems and facility operations–often completed in just one or two days

-

Avoid Costly Replacements: Extend the service life of corroded chillers and heat exchangers without the long lead times and expense of full equipment replacement

-

Restore System Efficiency: Rebuilds restore thermal transfer performance, helping chillers and exchangers run reliably and reduce energy waste

-

Stop Corrosion For Good: Belzona coatings eliminate galvanic and crevice corrosion, protecting against further metal loss and unplanned failures

-

Long-Term Durability: Repairs last for years–often decades–delivering high ROI and reducing maintenance frequency

-

No Hot Work Required: Belzona materials cure at room temperature, improving job site safety and eliminating fire watch or shutdown requirements

-

Tailored to Demanding Environments: Specialized epoxies and coatings resist high temperatures, harsh chemicals, and erosion in continuous immersion service

-

Protect Your Reputation: Avoid facility shutdowns and occupant complaints by keeping HVAC systems online in hospitals, schools, hotels, data centers and production environments

Need Help With Chiller Repair?

Request an estimate or consultation.

A BIG technician performs tube sheet coating during chiller repair and restoration.

Why Mechanical Contractors Trust BIG?

Mechanical contractors trust Banks Industrial Group for quick, cost-effective Belzona repairs that enhance efficiency and extend equipment life without lengthy replacement downtime.

- Tailored, Problem-Solving Approach: BIG collaborates with clients to deliver practical, cost-effective repair solutions—never overselling or applying unnecessary fixes

- Proven Belzona Expertise: We use high-performance Belzona materials to deliver repairs that are as strong as (or stronger than) metal, extending equipment life, and protecting your investment

- Speed Without Compromise: Our cold-applied, fast-curing techniques minimize downtime, with most repairs completed in just days—not weeks—keeping your operation running

- Versatile Repairs for Complex Needs: From severe heat exchanger corrosion to chemical and biological attack, BIG brings the right materials and in-house expertise to tackle the toughest repair challenges

- Safety You Can Trust: With 100% of our team OSHA 30 certified and top-tier ISNetworld safety ratings, BIG ensures every job is done safely and responsibly

- Offer value-added service to your clients by recommending an expert repair solution that enhances system longevity

BIG Chiller Repair Examples

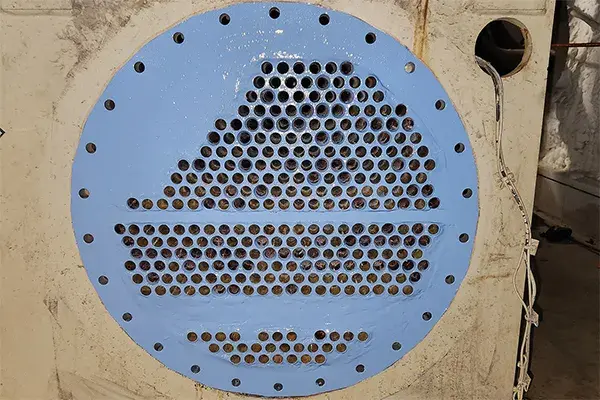

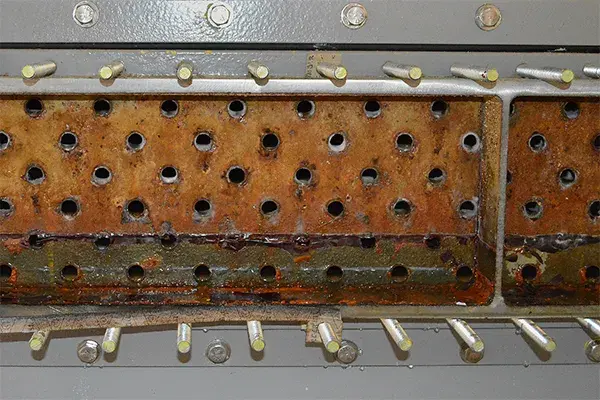

Before: tube sheet corrosion hurts efficiency and increases risk of failure.

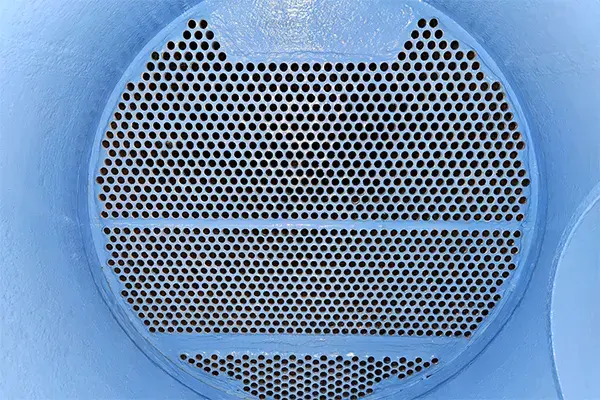

After: Belzona chiller coating restores lost efficiency and protects against corrosion.

Deteriorated Chiller Tube Sheet Repair

During a maintenance check before the spring start-up, corrosion was found on this chiller's tube sheets. Banks Industrial Group was called in to repair and protect the tube sheets and end caps, aiming to prevent future corrosion and extend their lifespan. The project was completed in three days.

Before: Corrosion and scale in the water box and tube sheet create a problem.

Grit blasting and chiller coating return lost efficiency and extend service life.

Chiller Tube Sheet & Water Box Refurbishment

A large water-cooled chiller in a Philadelphia office building was losing efficiency due to tube sheet corrosion and scale build-up. BIG removed the damage, applied a protective coating, and restored performance in just 5 days, preventing leaks and improving long-term reliability.

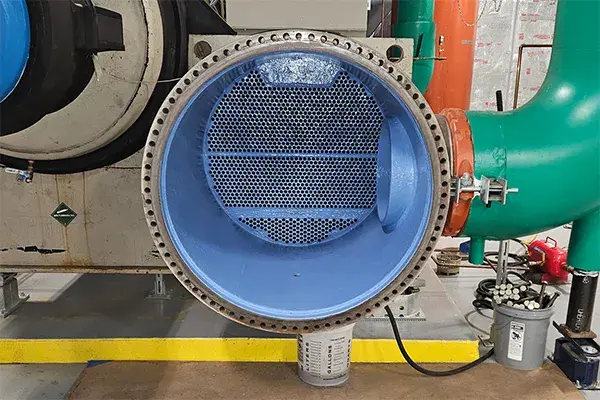

Chiller tube sheet ready for metal repair and protective coating.

Three tube sheet sets restored using Belzona chiller coatings.

Fast Chiller Tube Sheet Restoration

Tube sheet corrosion found during fall maintenance was reducing efficiency and risking leaks in chillers at a government operations center. BIG restored three tube sheets with prep, resurfacing, and protective coating—all completed in just 4 days.

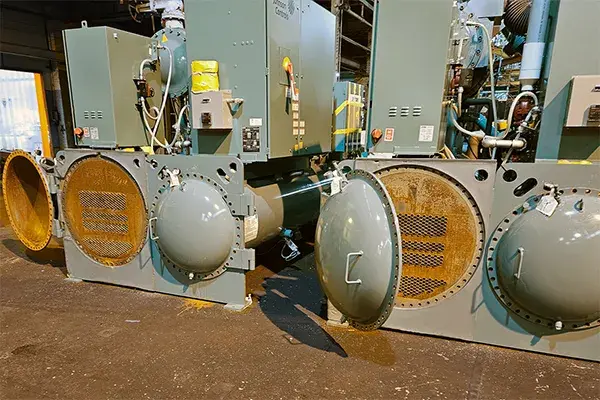

New chillers await protective coating application prior to installation.

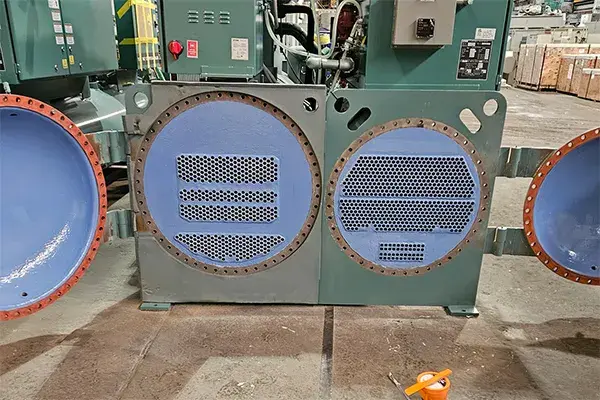

Belzona chiller coating applied to tube sheets and end caps.

New Chiller Tube Sheet Coating

BIG applied a protective coating to the evaporator and condenser tube sheets of two new water-cooled chillers. This proactive step prevents corrosion, ensuring the chiller's integrity and extending its lifespan. As a result, maintenance costs are reduced, and performance is improved over time.

Before: Corrosion and rust on the heat exchanger tube sheet.

After: Heat exchanger tube sheet coating applied during refurbishment.

Heat Exchanger Coating

BIG grit blasted, resurfaced, and coated the corroded tube sheets on two military heat exchangers. Rust and metal loss had decreased their efficiency and risked failure. Our specialized Belzona protective coatings were used to restore efficiency and prevent future corrosion.

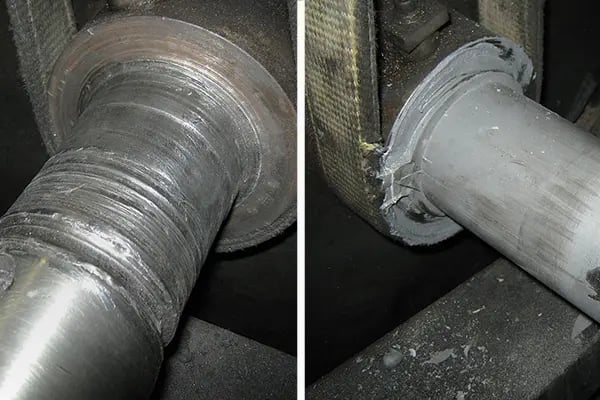

Before: Severe metal loss from corrosion and erosion on chiller end cap.

After: Metal loss pitting is filled and protective coating applied.

Chiller End Cap Corrosion Restoration

We repaired the corroded chiller end cap by removing corrosion and scale with grit blasting, exposing metal loss and pitting. We then filled the pitted areas with Belzona metal repair paste and applied a protective coating to prevent future corrosion.

Before: Chiller end cap cannot be used because of a major metal crack.

After: The chiller end cap has been restored, coated, and is ready for use.

Cracked Chiller End Cap Repair

This cracked end cap was successfully rebuilt using Belzona materials. We began by grit blasting the metal and cutting the cracks to make them uniform. Next, we filled damaged areas with ceramic metal paste, then reinforced with a carbon fiber composite. Finally, we applied a protective coating.

Before: Corrosion under insulation on this economizer created a thin-wall condition.

After: Corrosion repaired with Superwrap and Belzona protective coating.

Chiller Economizer Corrosion Repair

Corrosion under insulation weakened the pipe walls and shell of this chiller economizer. To fix this, we used Superwrap and added protective coatings to stop future corrosion. Superwrap is a cost-effective solution, especially given the high expenses, long wait times, and difficult access to these parts.

Before: Compressor elbow was damaged due to corrosion under insulation.

After: Superwrap was applied to the elbow, restoring structural integrity.

Chiller Compressor Elbow Corrosion Repair

The compressor elbow of this water-cooled chiller was damaged by corrosion under insulation due to pipe sweating near the flanges and insulation joints. We used Belzona Superwrap II to restore its strength and applied protective coatings to prevent future moisture damage

Before: Corrosion damage found under the insulation at the evaporator inlet.

After: Superwrap adapts to this complex shape for an efficient on-site repair.

Evaporator Inlet Corrosion Repair

The insulated inlet of this chiller's evaporator corroded due to trapped condensation. We used Belzona Superwrap II for an on-site repair. Superwrap allowed for a fast fix because it can adapt to complex shapes. See our chiller CUI case study for more about this repair.

Before: Extensive rust and metal damage due to CUI on the chiller barrel.

After: We removed the rust and applied a protective coating to prevent corrosion.

Chiller Barrel Corrosion Under Insulation Repair

Severe corrosion under insulation on the exterior evaporator barrel of this chiller was grit blasted and protective coated using specialized Belzona. This will protect against future corrosion after the insulation is replaced.

Tube Sheet Repair Case Study with Step-by-Step Photo Documentation

Read about the tube sheet restoration of corroded chillers on the 12th floor of a Jersey City hotel. Banks Industrial Group provided a fast, durable, and cost-effective solution that minimized disruption, safeguarded revenue, and delivered long-term HVAC asset protection.

BIG provides restoration and coating service for corroded chillers and heat exchangers

We specialize in the rebuild and coating of corroded chiller and heat exchanger components. We design corrosion repair solutions that fit the site requirements and operating conditions of our clients in commercial, institutional and industrial settings. Our field technicians are validated composite repair personnel who bring a strong work ethic and safety commitment to each project. We work efficiently – minimizing downtime, and getting your operation running again as fast as possible. Trust BIG to cover your chiller coating and heat exchanger repair needs! Call 856-687-2227 or email our corrosion repair experts today for a fast quote.